NB Miata with Ford 3V V8 4.6litre Modular Motor with Tremec 5 speed from a Mustang GT

#1

This is my second Monster Miata (first one was rough as a bears a$$) aiming for a near to OEM look and feel on this.

I have a stock standard NB black on black (apart from Nexus Tablet for audio and gps etc)

170k km on original motor without a trouble in the world - I bought the car about 18months ago intending to do the V8 - its time !

I found a Ford Modular V8 in an "engine yard" close to me complete with tremec box - not the T56 but a TR3650

so far I have got the following bits nailed down

1) coilovers and custom springs from GAZ (uk based company)

2) Megasquirt 3 ecu

3) Aeromotive 340litre per hour fuel pump

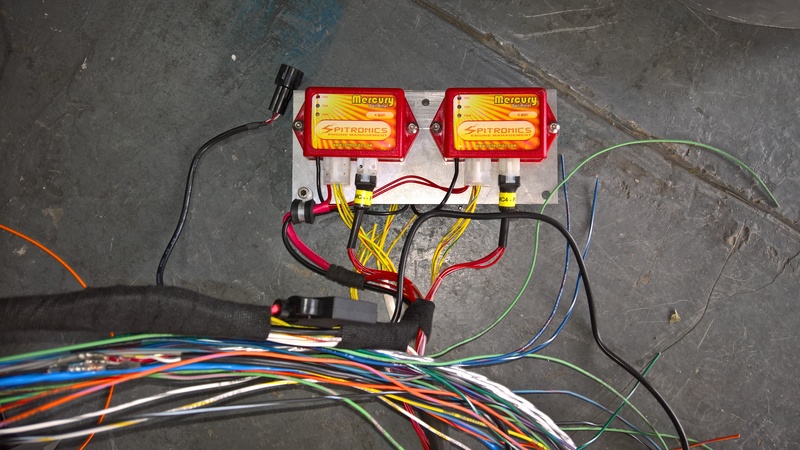

4) new MSD coils for the 4.6

Still looking to figure out

rear end

brakes

power steering (use Mazda pump mounted to Ford engine or adapt Ford compressor to Mazda or go with an electric power steering pump)

Aircon (use Mazda compressor mounted to Ford engine or adapt Ford compressor to Mazda)

Radiator and header tank etc

I have got prices from Martin on his rear end kit but the shipping kills and is literally more than the component cost

here are some pics

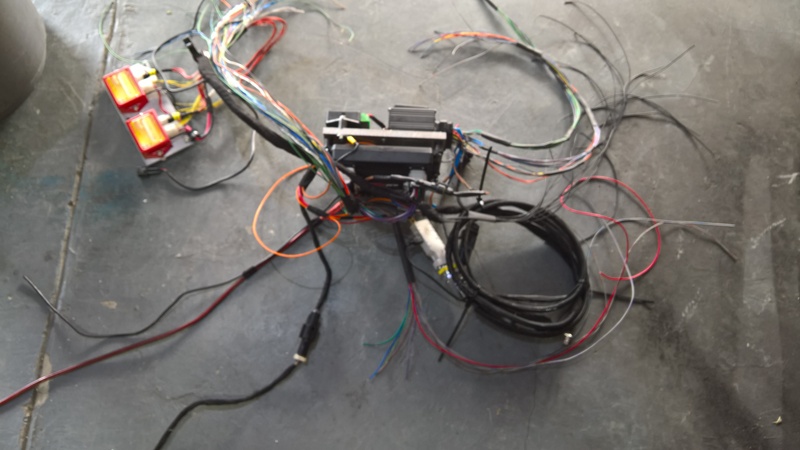

so far I have stripped the motor down a bit and started building the custom wiring harness and adding sensors I want - since the Mustang doesnt use a coolant sensor it has a cylinder head temp sensor and an oil temp sensor (broken on my motor), the mustang dbw throttle has been replaced with a manual throttle body, new coils are on (2 bloody spark plugs are broken and stuck, waiting on summit for the lisle tool to remove them)

the motor seems incredibly clean on the inside - like no sludge or anything ! just a very clean motor internally

I am hoping to get the oem mazda motor out in the next month and start on frame rail trimming and subframe - in the meantime I hope to sort out my diff and axles (all ideas welcome) and any ideas comments on the build - ideas a bout power steering and possible electric power steering pump ?

I have a stock standard NB black on black (apart from Nexus Tablet for audio and gps etc)

170k km on original motor without a trouble in the world - I bought the car about 18months ago intending to do the V8 - its time !

I found a Ford Modular V8 in an "engine yard" close to me complete with tremec box - not the T56 but a TR3650

so far I have got the following bits nailed down

1) coilovers and custom springs from GAZ (uk based company)

2) Megasquirt 3 ecu

3) Aeromotive 340litre per hour fuel pump

4) new MSD coils for the 4.6

Still looking to figure out

rear end

brakes

power steering (use Mazda pump mounted to Ford engine or adapt Ford compressor to Mazda or go with an electric power steering pump)

Aircon (use Mazda compressor mounted to Ford engine or adapt Ford compressor to Mazda)

Radiator and header tank etc

I have got prices from Martin on his rear end kit but the shipping kills and is literally more than the component cost

here are some pics

so far I have stripped the motor down a bit and started building the custom wiring harness and adding sensors I want - since the Mustang doesnt use a coolant sensor it has a cylinder head temp sensor and an oil temp sensor (broken on my motor), the mustang dbw throttle has been replaced with a manual throttle body, new coils are on (2 bloody spark plugs are broken and stuck, waiting on summit for the lisle tool to remove them)

the motor seems incredibly clean on the inside - like no sludge or anything ! just a very clean motor internally

I am hoping to get the oem mazda motor out in the next month and start on frame rail trimming and subframe - in the meantime I hope to sort out my diff and axles (all ideas welcome) and any ideas comments on the build - ideas a bout power steering and possible electric power steering pump ?

#2

I have never seen a 4.6 in a Miata before. I do not know the exact detentions of the motor but it looks very wide. The angle of the V on that motor looks almost 90 degree. Before you tear the 4 banger out of there do alot of measuring. I am very interested to see how this will go down. If it works the 4.6 would be a viable and cheap option for my next build.

#3

the Modular ford is WIDE - it is a 90deg V8 - I would do this with the Modular SOHC but definitely not the DOHC

I will post some measurements later - across the OEM exhaust manifolds its .5cm narrower than a Lexus V8 with its OEM exhaust manifolds so I know the Lexus fits so this one will as well - the unknown here is the bulkiness of the Ford heads and whether they will make contact above the frame rails with anything (the gussets by the shock towers come to mind)

it will need headers - to go straight down and then turn

the frame rail corners cut (potentially frame rail lip removed) but this may not need to be done

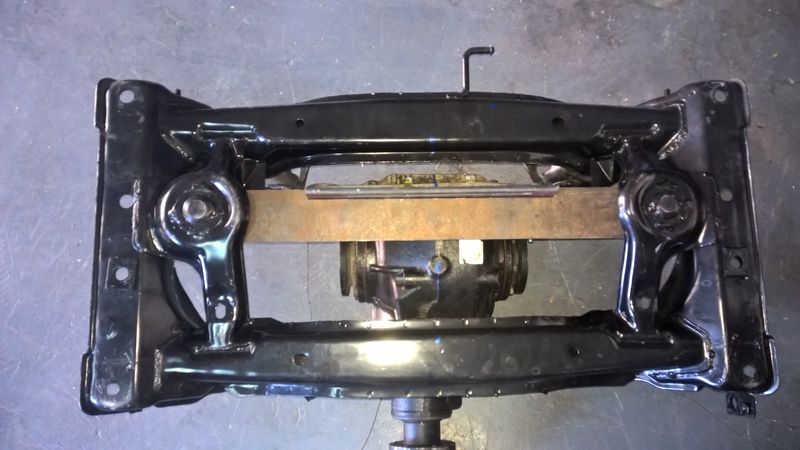

The modular is rear sump (from the Mustang anyway) so that makes it really easy to drop in - I could modify the oem subframe but have got a V8Roadsters one on order to do most of the mockup / header build and design and such out of the car -

I will post some measurements later - across the OEM exhaust manifolds its .5cm narrower than a Lexus V8 with its OEM exhaust manifolds so I know the Lexus fits so this one will as well - the unknown here is the bulkiness of the Ford heads and whether they will make contact above the frame rails with anything (the gussets by the shock towers come to mind)

it will need headers - to go straight down and then turn

the frame rail corners cut (potentially frame rail lip removed) but this may not need to be done

The modular is rear sump (from the Mustang anyway) so that makes it really easy to drop in - I could modify the oem subframe but have got a V8Roadsters one on order to do most of the mockup / header build and design and such out of the car -

#4

heres some pics of the dimensions of the engine

The engine bay is literally 27.6 inches between the frame rail inners

so as it is it wont fit, the 4.6 SOHC modular 3v v8 across the widest part of the oem ford manifolds - measures out at 70cm / 27.5 inches about 36 cm from sump base

thats obviously excluding the oem header to downpipe flanges - which wont exist on my headers - i am making new headers so will cut that clearance down by at least 2.5cm / 1 inch a side

so the frame rails may need to be trimmed for maintenance and bolt access - other pics of overall height from sump base to intake manifold are height of 72cm /28.3 inches

(yes the headers are on backwards on the motor as its easier to grab with a strap like that)

The engine bay is literally 27.6 inches between the frame rail inners

so as it is it wont fit, the 4.6 SOHC modular 3v v8 across the widest part of the oem ford manifolds - measures out at 70cm / 27.5 inches about 36 cm from sump base

thats obviously excluding the oem header to downpipe flanges - which wont exist on my headers - i am making new headers so will cut that clearance down by at least 2.5cm / 1 inch a side

so the frame rails may need to be trimmed for maintenance and bolt access - other pics of overall height from sump base to intake manifold are height of 72cm /28.3 inches

(yes the headers are on backwards on the motor as its easier to grab with a strap like that)

#5

Any progress?

I thought about using a Coyote V8. Yes, I know it "doesn't fit".

I would cut away the frame rails and fabricate a tube front end incorporating the V8R subframe.

All it would take is time, money and skills.

I thought about using a Coyote V8. Yes, I know it "doesn't fit".

I would cut away the frame rails and fabricate a tube front end incorporating the V8R subframe.

All it would take is time, money and skills.

#6

its getting there

finished sourcing most of the parts

brakes

coilovers

ecu - busy making the rest of the harness at present

drawn up the parts for rear diff mount - waiting on laserjet cutting to be done

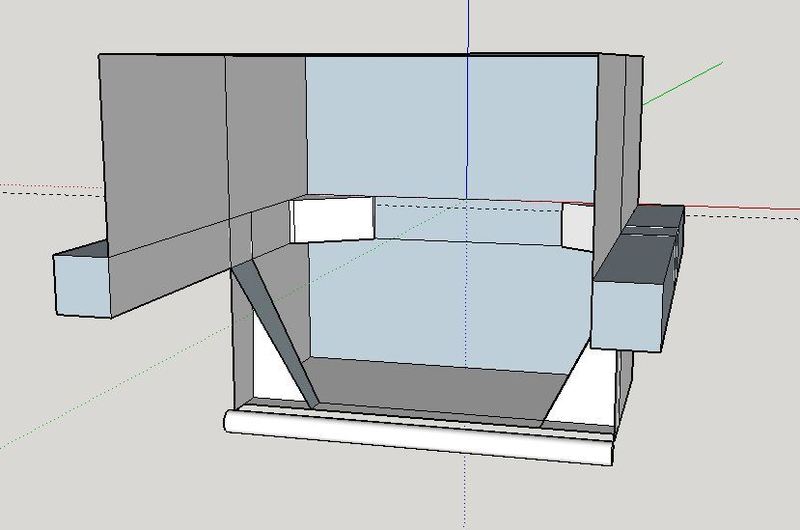

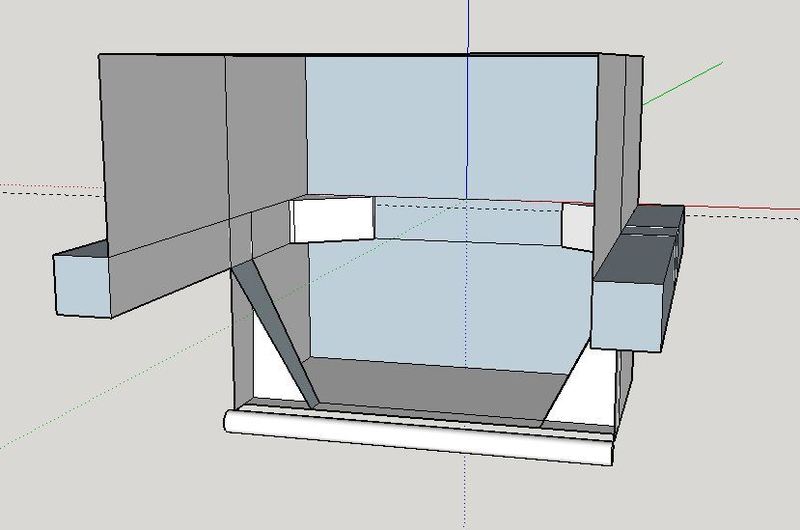

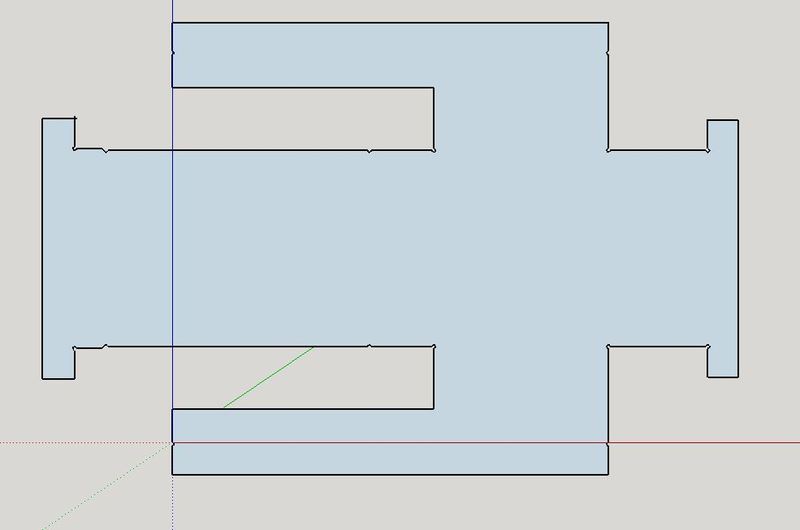

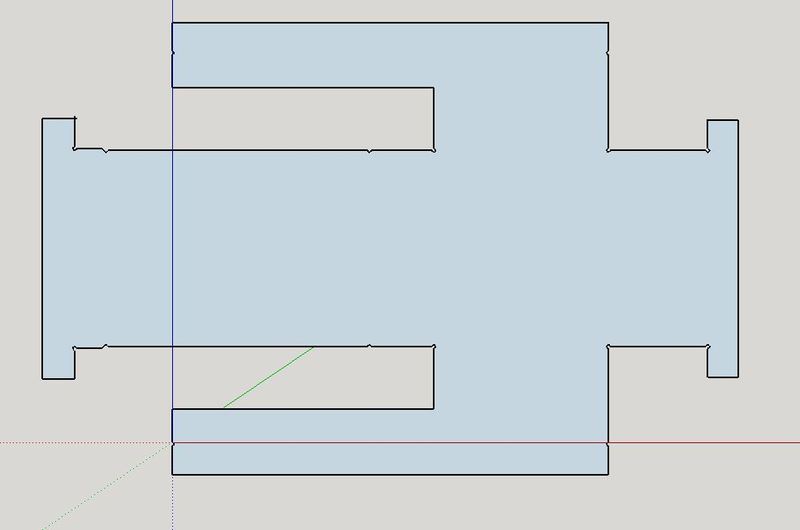

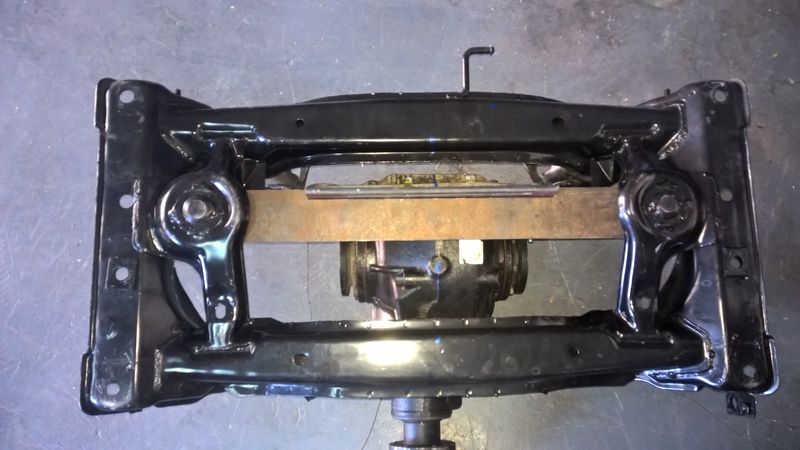

to check the fit I drew up the engine bay in CAD

[IMG] [/IMG]

[/IMG]

its not perfectly done - need to do some more work on the subframe - but you get the idea - the frame lips are removed, I have left the corner triangles in place for an idea on clearance - I know they not triangular but have you tried to draw that shape in CAD - I couldnt my CAD skills suck

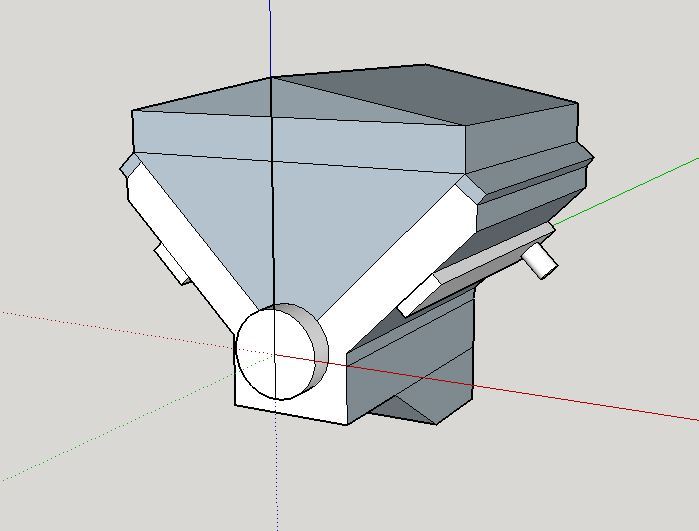

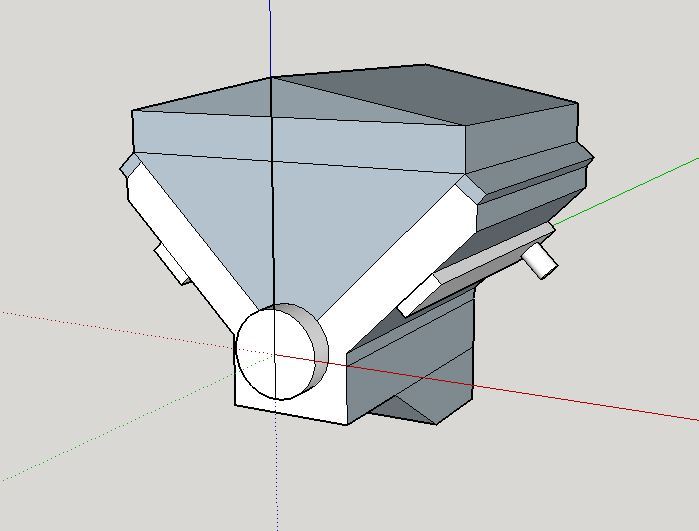

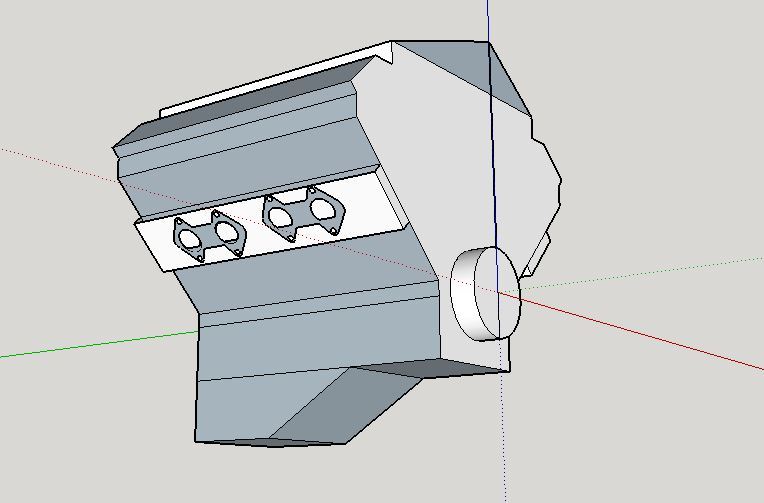

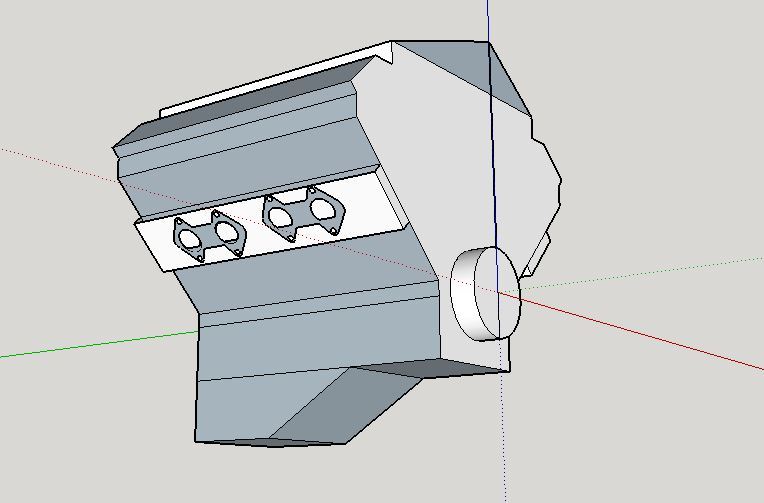

then I drew up the Modular V8 - I didnt fill in all the details just the rough shadow of the external dimensions - the sump is drawn 40mm too deep as the motor is standing on its sump on the floor so the floor of the sump is just an estimate - will keep refining

[IMG] [/IMG]

[/IMG]

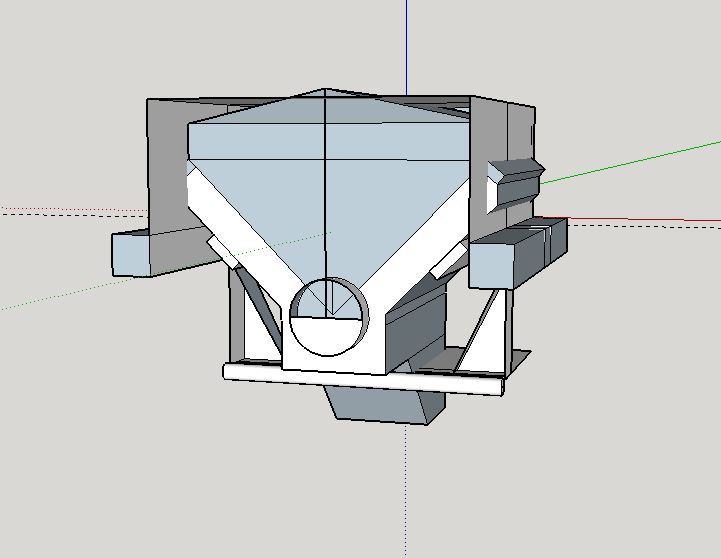

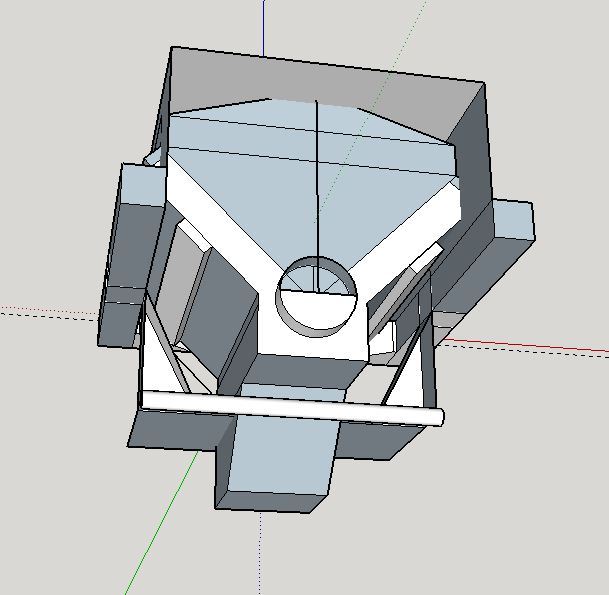

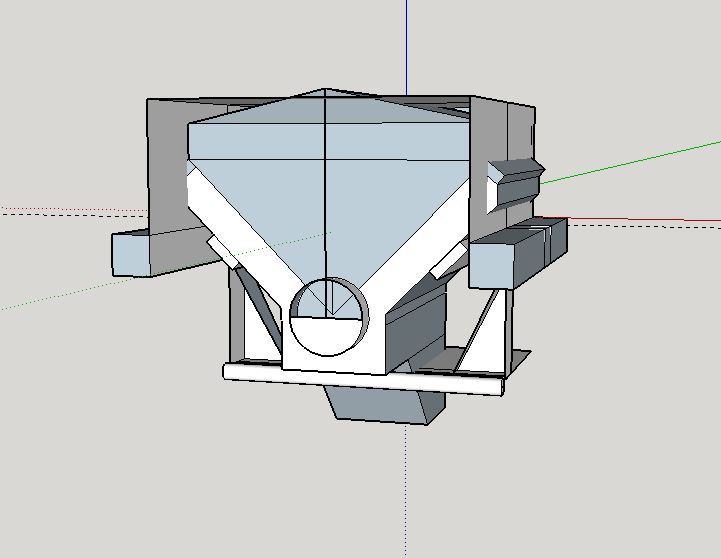

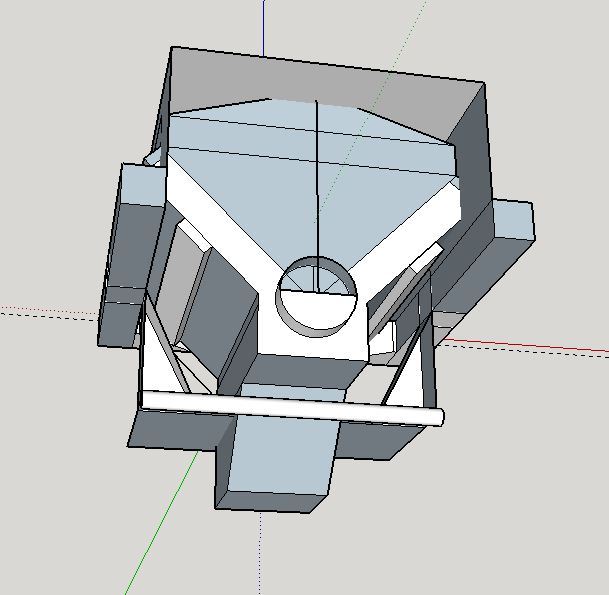

then I overlaid the two

so it fits and so would the coyote v8

normal trimming will be needed on the inner bay triangles, the frame lips may stay need to work out feasability of headers and fitment

i will have to really refine the drawing and get the subframe drawn 100%

but for a start I am quite happy with the first draft

if anyone wants to sketchup drawing let me know

finished sourcing most of the parts

brakes

coilovers

ecu - busy making the rest of the harness at present

drawn up the parts for rear diff mount - waiting on laserjet cutting to be done

to check the fit I drew up the engine bay in CAD

[IMG]

[/IMG]

[/IMG]its not perfectly done - need to do some more work on the subframe - but you get the idea - the frame lips are removed, I have left the corner triangles in place for an idea on clearance - I know they not triangular but have you tried to draw that shape in CAD - I couldnt my CAD skills suck

then I drew up the Modular V8 - I didnt fill in all the details just the rough shadow of the external dimensions - the sump is drawn 40mm too deep as the motor is standing on its sump on the floor so the floor of the sump is just an estimate - will keep refining

[IMG]

[/IMG]

[/IMG]then I overlaid the two

so it fits and so would the coyote v8

normal trimming will be needed on the inner bay triangles, the frame lips may stay need to work out feasability of headers and fitment

i will have to really refine the drawing and get the subframe drawn 100%

but for a start I am quite happy with the first draft

if anyone wants to sketchup drawing let me know

#9

the exhaust flanges are the "white" blocks on the v of the engine

i am trying to draw them in with the flanges and some 90 degree bends but not getting much success - will keep at it

[IMG] [/IMG]

[/IMG]

I know theres enough room width wise as I did a lexus v8 previously and that motor is about 20mm wider across the important part on the heads - the concern on this v8 is clutch master cylinder clearance - need to figure that next

i am trying to draw them in with the flanges and some 90 degree bends but not getting much success - will keep at it

[IMG]

[/IMG]

[/IMG]I know theres enough room width wise as I did a lexus v8 previously and that motor is about 20mm wider across the important part on the heads - the concern on this v8 is clutch master cylinder clearance - need to figure that next

#11

For power steering, you may look into using the Miata pump on the Ford accessory drive. Its been done on an LS before, I'll see if I can find it. Other than that, people modify the plumbing between (for you) the ford pump and the Miata rack to make it all bolt up. You will likely require a restrictor in the pressure line or you will have an over-compensating system. Turn One

The LSx series of motors are 90 degree V8s. Mod motors actually have a 120 degree bank, which is why they look so different, and much wider, than other V8s.

What car did you pull it out of? Good luck on the project, I recall you talking about it.

The LSx series of motors are 90 degree V8s. Mod motors actually have a 120 degree bank, which is why they look so different, and much wider, than other V8s.

What car did you pull it out of? Good luck on the project, I recall you talking about it.

#12

For power steering, you may look into using the Miata pump on the Ford accessory drive. Its been done on an LS before, I'll see if I can find it. Other than that, people modify the plumbing between (for you) the ford pump and the Miata rack to make it all bolt up. You will likely require a restrictor in the pressure line or you will have an over-compensating system. Turn One

The Ford modular engines are in fact 90 degree V8's. They are just wider than Chevy LSx series engines due to the heads having over head cams (one atop each head in the SOHC designs and two atop each head in the DOHC designs, including the Coyote). Thus extending the width of the engine.

#13

i was actually thinking of an electric power steering pump in the trunk and running the lines forward to the rack and then a return to the trunk

or else i need a ford explorer power steering pump

the electric pump in the trunk really appeals

or else i need a ford explorer power steering pump

the electric pump in the trunk really appeals

#15

ok so to get this big a$$ mod motor to fit I need to reduce its height a bit

looking to shrink it 100mm down

i bolted the oem sump to a table - sliced off a wedge of 80mm to reduce the depth of the sump

then i gave up on that and drew the sump in trusty cad and sent that off for water jet cutting

heres a few pics of the sump being shrunk - will work perfectly but i decided to then make an ally one

also hoping to be able to remove the cmrc plates between the intake and cylinder heads to reduce height in that area too - dont want to cut the hood

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

looking to shrink it 100mm down

i bolted the oem sump to a table - sliced off a wedge of 80mm to reduce the depth of the sump

then i gave up on that and drew the sump in trusty cad and sent that off for water jet cutting

heres a few pics of the sump being shrunk - will work perfectly but i decided to then make an ally one

also hoping to be able to remove the cmrc plates between the intake and cylinder heads to reduce height in that area too - dont want to cut the hood

[IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG]

#16

so the oem sump cut down worked out well enough but i wanted it better so i drew up a flat plate cutout

The water jet guy called me up too late on Friday to collect it

I need to get it bent / drilled / welded for test fit asap

[IMG] [/IMG]

[/IMG]

hope it turns out the way I want it - it should have just over 4.3 litres in the sump

The water jet guy called me up too late on Friday to collect it

I need to get it bent / drilled / welded for test fit asap

[IMG]

[/IMG]

[/IMG]hope it turns out the way I want it - it should have just over 4.3 litres in the sump

#17

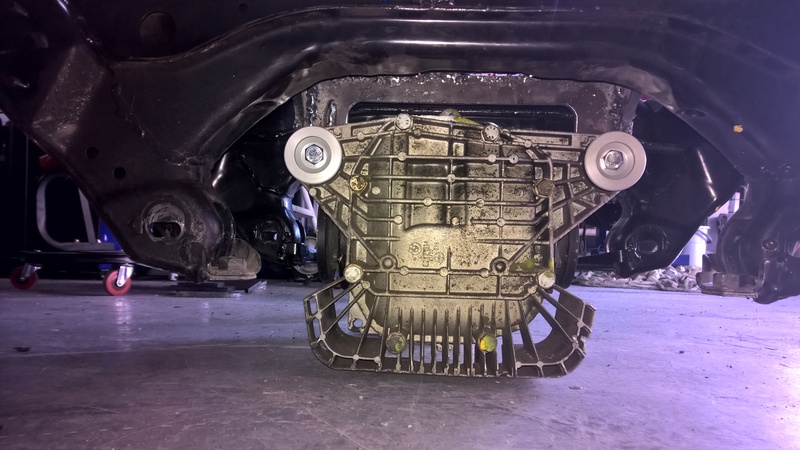

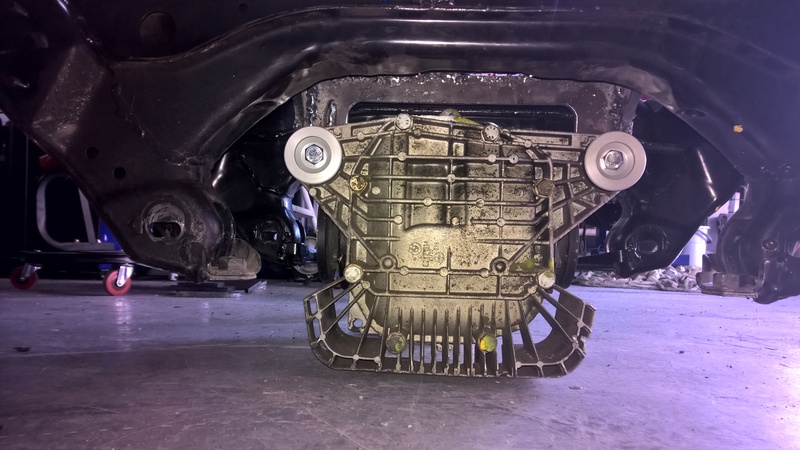

so after debating the costs of bringing in a diff / mount / cv setup and finding that it was simply crazy - cost to me for a rear end kit was well over 5k usd all said and done - I decided to go where no one has gone before........

1 x BMW E46 M3 LS diff

custom mounts

and we worry about axles and cvs later (grafting M3 cvs / porsche 930 cvs / sandrail axle makers etc) i figure i can get something solved

I must say Martin was incredibly helpful in this regard but the total cost was just silly

so far I am into the rear end for 650 dollars (spare subframe, bmw diff and water jet cutting and new diff bushes)

what are your thoughts on this route ?

these are not the final mounts - this was a test and also got a new welder so i learnt the welders new settings - huge difference coming from an old transformer based stick welder to a IGBT transistorised one - such an improvement !

have drawn up some new mounts to move the diff back and tuck it up under the subframe

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

1 x BMW E46 M3 LS diff

custom mounts

and we worry about axles and cvs later (grafting M3 cvs / porsche 930 cvs / sandrail axle makers etc) i figure i can get something solved

I must say Martin was incredibly helpful in this regard but the total cost was just silly

so far I am into the rear end for 650 dollars (spare subframe, bmw diff and water jet cutting and new diff bushes)

what are your thoughts on this route ?

these are not the final mounts - this was a test and also got a new welder so i learnt the welders new settings - huge difference coming from an old transformer based stick welder to a IGBT transistorised one - such an improvement !

have drawn up some new mounts to move the diff back and tuck it up under the subframe

[IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG]

#20

Some thinks me way out by using a RX-7TT rear complete, but now I have almost unlimited racing gear sets better somewhat cheaper brakes , and did I mention TOE adjustment to keep the tail happy little car in line . I loved my 02 M3 and the rear never gave me a lick of trouble. It did et rear tires however/hmmmm...too much throttle inches on my part...Keep your plan its a good one!!

#21

Wow great progress! This is a really interesting build I love it!

+1 on the diff being at least 3 inches too low. That is easily going to be the lowest point of the car and it's not going to end well like that.

+1 on the diff being at least 3 inches too low. That is easily going to be the lowest point of the car and it's not going to end well like that.

#22

ok so a little summit box arrived with some crown vic engine mounts

they fit the motor beautifully but on the left side of the motor they wont need a lot of work to fit the v8 roadsters subframe however on the right side (where the steering column goes for me) its not going to work

I have to contend with the engine mount / aircon / starter / steering column and somehow get an exhaust through all that - from pics i thought it may work but it was always going to be dicey - but at least the left side is taken care of - check the space issues on the right hand side - the ally square tubing is an approximation of the steering shaft

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

so back to the drawing board for the (drivers) right side mount - I will probably keep the left side mount as it would be really easy to make work

was aiming for as much bolt on parts as possible

I am also thinking of treating the mod motor like a lsx and putting flat plates against the block and bolting ls style mounts to that and then having a pedestal come up to mount it - if i hadnt ordered a mountless subframe and were doing this again i would order up a lsx mount style subframe - so a tip for the next guy is to treat the mod motor as a lsx

I am still waiting for the water jet guy to do the sump cutting for me - the damn holidays are slowing that one down

they fit the motor beautifully but on the left side of the motor they wont need a lot of work to fit the v8 roadsters subframe however on the right side (where the steering column goes for me) its not going to work

I have to contend with the engine mount / aircon / starter / steering column and somehow get an exhaust through all that - from pics i thought it may work but it was always going to be dicey - but at least the left side is taken care of - check the space issues on the right hand side - the ally square tubing is an approximation of the steering shaft

[IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG]so back to the drawing board for the (drivers) right side mount - I will probably keep the left side mount as it would be really easy to make work

was aiming for as much bolt on parts as possible

I am also thinking of treating the mod motor like a lsx and putting flat plates against the block and bolting ls style mounts to that and then having a pedestal come up to mount it - if i hadnt ordered a mountless subframe and were doing this again i would order up a lsx mount style subframe - so a tip for the next guy is to treat the mod motor as a lsx

I am still waiting for the water jet guy to do the sump cutting for me - the damn holidays are slowing that one down

#24

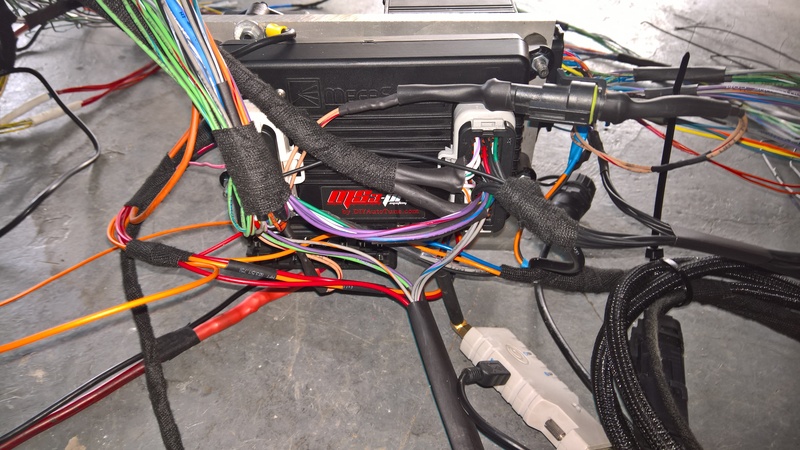

ok so a few updates for now

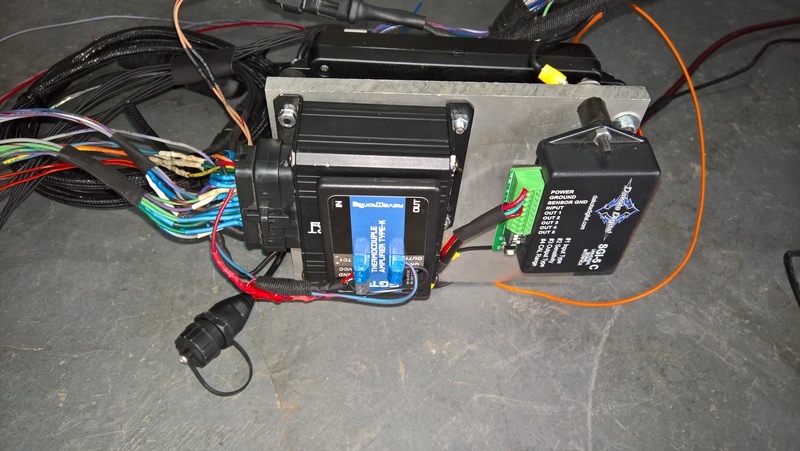

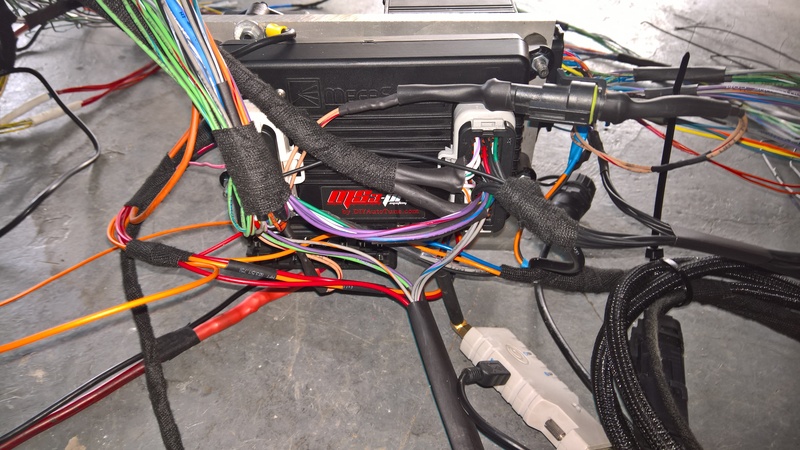

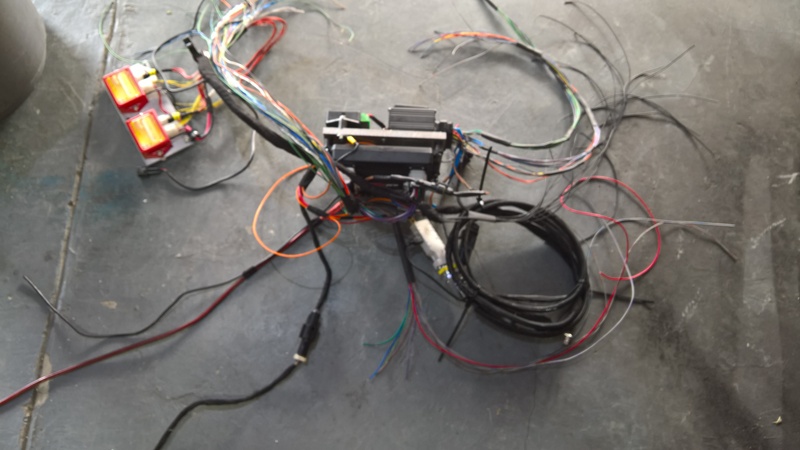

did some wiring.....

got new mounts for the diff back - tacked those up

got the new flat pack sump back - decided i need a proper welder - this no gas mig is a splatter king

did some wiring.....

got new mounts for the diff back - tacked those up

got the new flat pack sump back - decided i need a proper welder - this no gas mig is a splatter king

#25

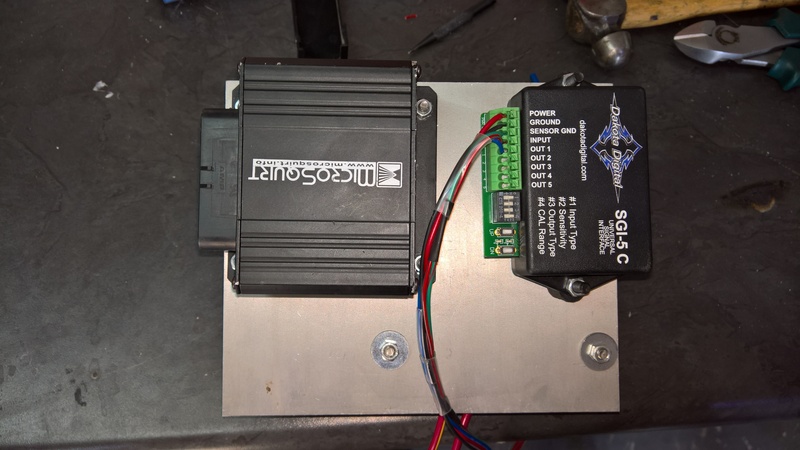

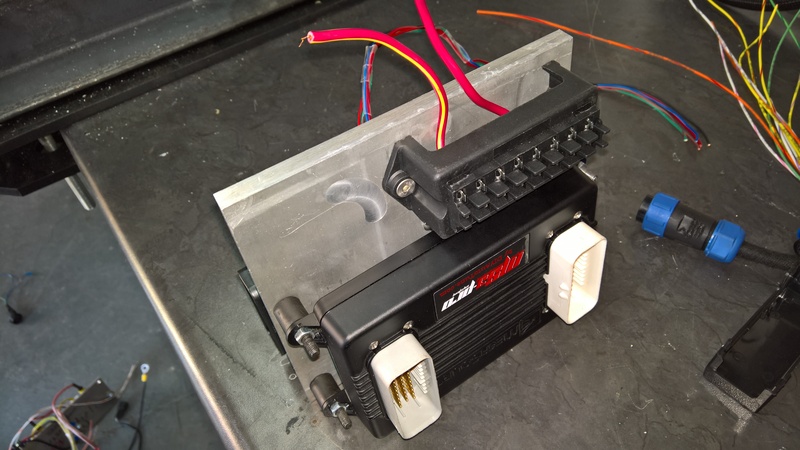

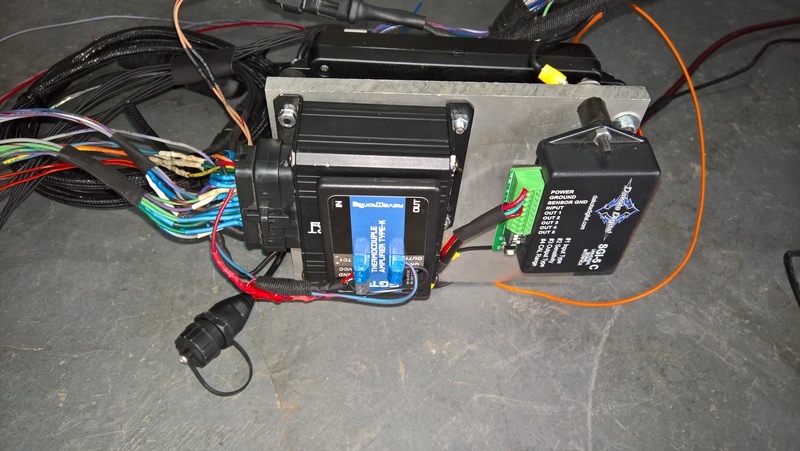

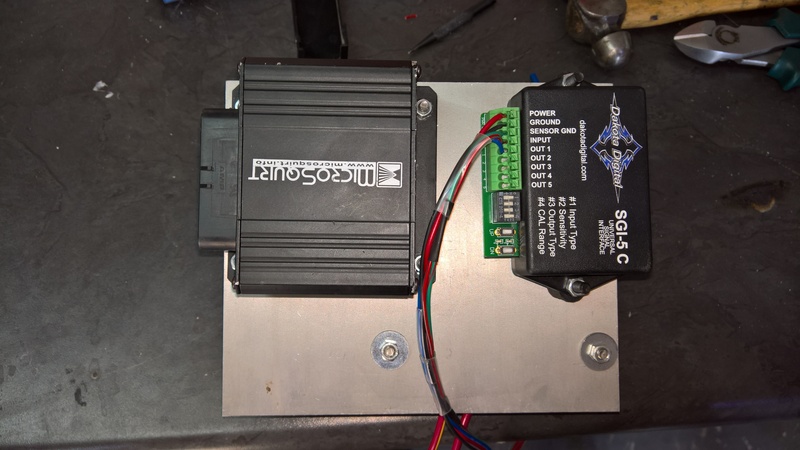

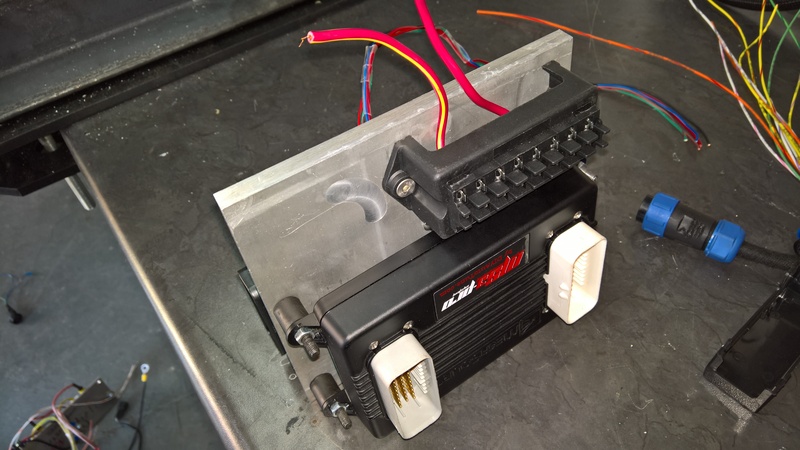

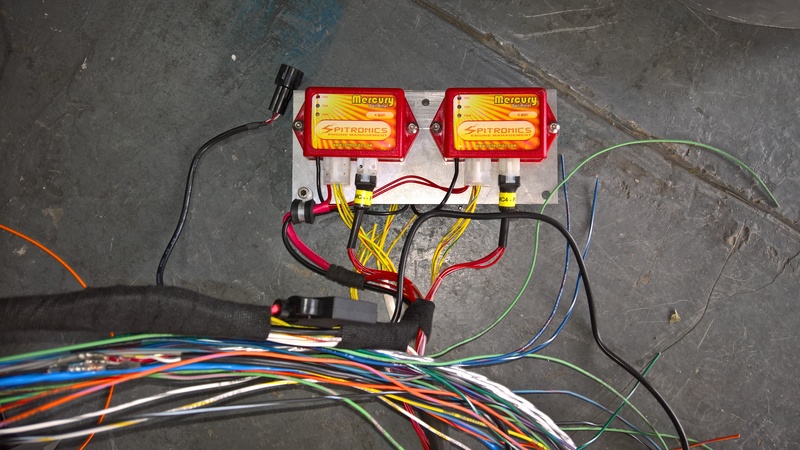

made a mount and a got a start on the underdash wiring

i am using the following items

MS3 PRO

Microsquirt v2

Dakota digital speedo converter box

Spitronics coil ignitors

innovate lc1 wideband

man I am glad I had an old Microsquirt lying around - I need it for all the extra inputs ! it will run can bus between the two ecus - I think I have gone a bit overboard

so far I am monitoring

1) fuel temp

2) fuel pressure

3) ambient baro

4) Manifold pressure

5) oil pressure

6) oil temp

7) coolant temp

8) intake air temp

9) cylinder head temp

10) exhaust gas temp

11) nos pressure

then 8 coils to fire, 8 injectors in sequential mode, 2 cams for vvt, progressive nos and traction control on the ms3 via the oem wheel speed sensors

just looking for a "Manettino" style switch to activate / de activate these features

heres some pics and if anyone has an idea how to make this neat let me know !!! its a spiders nest and only part way done !!!! it gets so untidy and chaotic so damn quick

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

i am using the following items

MS3 PRO

Microsquirt v2

Dakota digital speedo converter box

Spitronics coil ignitors

innovate lc1 wideband

man I am glad I had an old Microsquirt lying around - I need it for all the extra inputs ! it will run can bus between the two ecus - I think I have gone a bit overboard

so far I am monitoring

1) fuel temp

2) fuel pressure

3) ambient baro

4) Manifold pressure

5) oil pressure

6) oil temp

7) coolant temp

8) intake air temp

9) cylinder head temp

10) exhaust gas temp

11) nos pressure

then 8 coils to fire, 8 injectors in sequential mode, 2 cams for vvt, progressive nos and traction control on the ms3 via the oem wheel speed sensors

just looking for a "Manettino" style switch to activate / de activate these features

heres some pics and if anyone has an idea how to make this neat let me know !!! its a spiders nest and only part way done !!!! it gets so untidy and chaotic so damn quick

[IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG]