Rich's 5.0 NA, boring stuff

#1

I bought my wife a mini cooper which she loved but an oil pump failure killed it so I sold it and bought her an NA, when she got pregnant it became mine since my truck got awful gas milage and we were breaking $4 a gallon. I started changing things until i flipped it in the summer. By that time my friend gave me a full mustang drivetrain, harness and ecu. The day after i crashed i picked up a clean NA with some minor mods. Luckily it was the same color as my hardtop. I have been driving it for a few months now and all i really did was port and polish the head and some minor stuff. Im almost ready to tear it apart, I get the rear tomorrow and headers by the end of the week.

#3

#5

Lookin' good. Now hurry up & finish so you can bring it to The Mitty. Glad to see that you apparently weren't injured in the flip.

Not knowing the circumstances, but, based on the recent driving incident; "You sure you wanna add big power to it?"

Not knowing the circumstances, but, based on the recent driving incident; "You sure you wanna add big power to it?"

#6

I was only doing 20-30 mph. Pick up hit me head on by my d-side front fender, put me off the road on the right, hit a rock, did a slow roll. Scraped my elbow trying to protect my head but the roll bar was good enough. The windshield frame folded like nothing.

The following users liked this post:

charchri4 (08-13-2015)

#12

Bought the axles and broched hubs from martin, $734. That puts me over $1000 for this project now. Not including the car of course. $1120 total, motor, trans, ecu, frame, gaskets etc, new alt, water pump, starter.

The following users liked this post:

charchri4 (08-13-2015)

#13

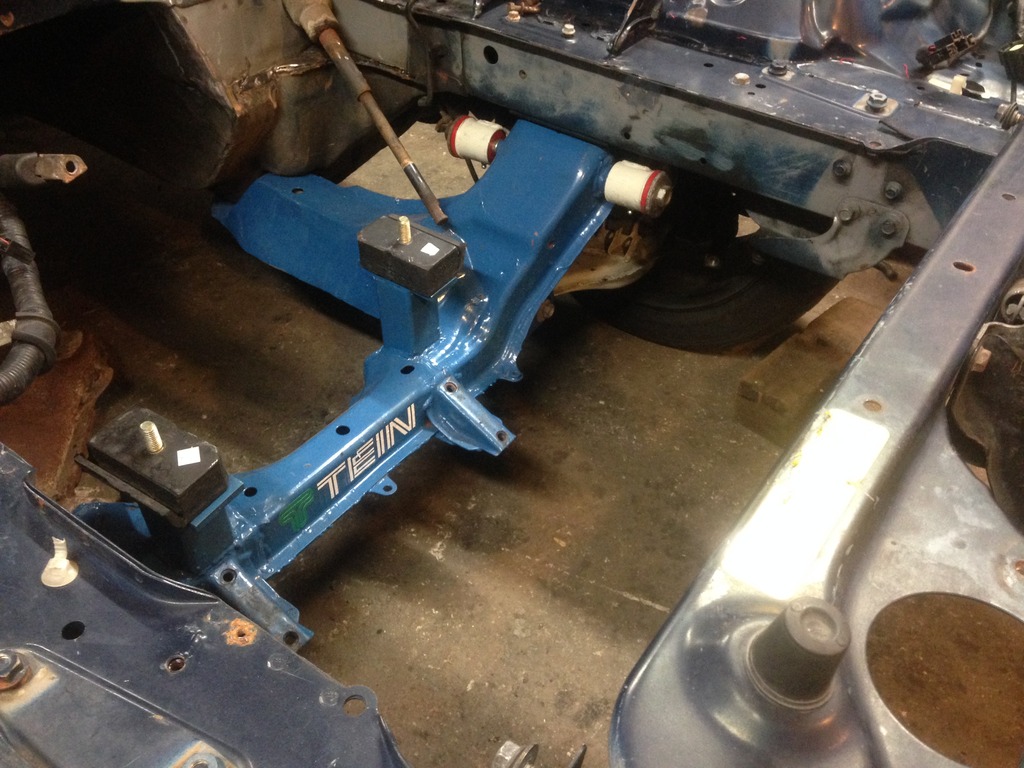

Started the swap, had the drive train and suspension out in about 3 hours, got both new subframes in with suspension in roughly 2 hours. Tackled the engine bay mods after that. Going to reattach the brakes and bleed the system so the rear end is complete when i get home. Also have to pull the passenger side seat for the ecu and start getting the harness in place. The motor and trans should be in by monday so I can order a drive shaft, havent found a shop by me yet. (Manhattan, bronx, westchester, putnam or dutchess county) if any one has any suggestions, danbury ct isnt far either. Ill post some pics when i upload them

#16

#17

#19

Sorry I missed this great build thread! Yes there are a couple plugs right there both having to do with AC. One for the clutch and the other for the AC fan.

Love the DIY work and super cheap build. Would like to see the cost build sheet when you are done. You give us all much hope! Really well done thank you for posting it.

Love the DIY work and super cheap build. Would like to see the cost build sheet when you are done. You give us all much hope! Really well done thank you for posting it.

#20

I'll be around 2 grand by the end. The rear end set up was the most (axles, diff, hubs, bushings) and Im still searching for an lsd so that will add another $100. This is what we can call phase 1. Next will be megasquirt with an ethanol sensor so I can run e85.

#21

Also if anyone has any specific questions or needs measurements feel free to ask.

Here are the specs

96 ecu, 1.8 with a 1.8 torsen and brakes on a 90

88 fox mustangs speed density

89-90 t5 from a 2.3 turbo using timkin ss202 pilot bearing and a useless 1st gear

Cougar 7.5 open for now

Martins axles and hubs

Crown vic water pump (std rotation)

Pm starter

Protane bushings

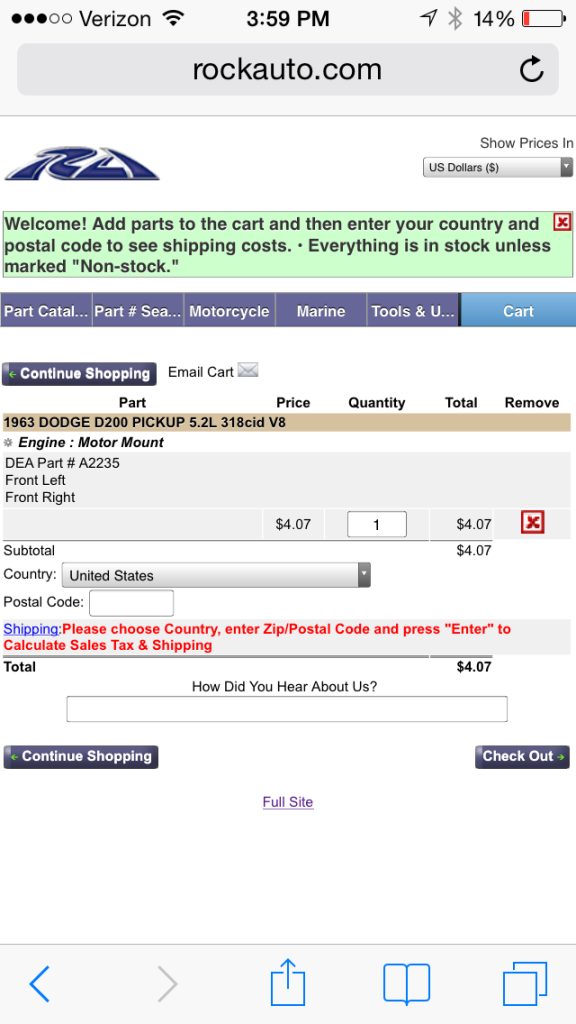

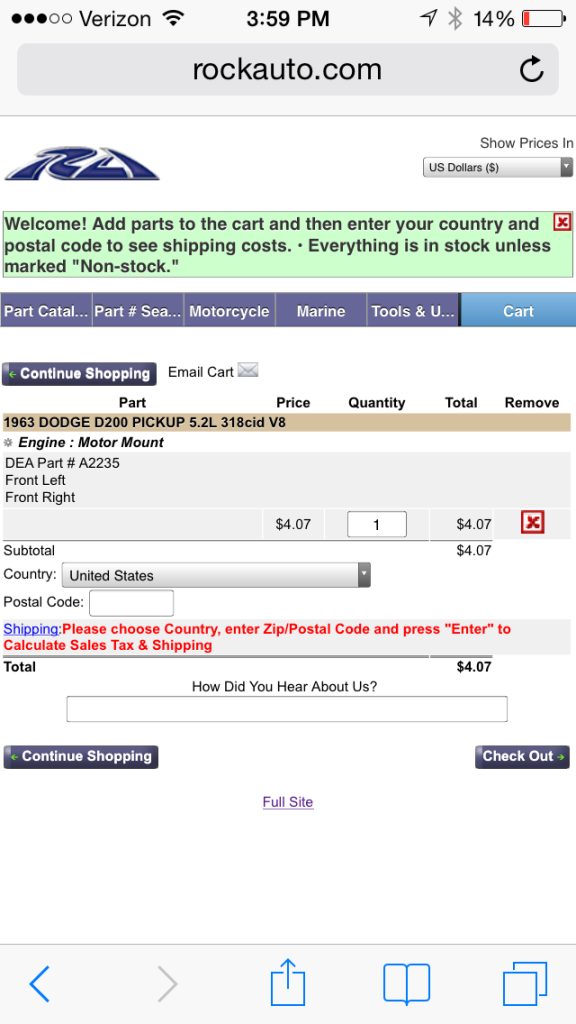

Dodge pickup motor mounts that martin uses $5. Each

Mismatched hedman headers. 88400Left and 89500 right. Like other members here. Its tight and did require more subframe modification. I also cut the cable guide for the clutch to have extra room. A lokar flexible dipstick was needed and so was a few light whacks where it passes the header.

Here are the specs

96 ecu, 1.8 with a 1.8 torsen and brakes on a 90

88 fox mustangs speed density

89-90 t5 from a 2.3 turbo using timkin ss202 pilot bearing and a useless 1st gear

Cougar 7.5 open for now

Martins axles and hubs

Crown vic water pump (std rotation)

Pm starter

Protane bushings

Dodge pickup motor mounts that martin uses $5. Each

Mismatched hedman headers. 88400Left and 89500 right. Like other members here. Its tight and did require more subframe modification. I also cut the cable guide for the clutch to have extra room. A lokar flexible dipstick was needed and so was a few light whacks where it passes the header.

Last edited by Richharr; 08-21-2015 at 10:43 PM. Reason: Add part numbers for member reference

The following users liked this post:

Lateralgeez (12-30-2015)

#22

No pics today. Got the trans mount all set up and finished so I can order a driveshaft. Alternator and starter wiring is done so it cranks. Fuel pump jumper is in and it quickly told me one of the o-rings is bad by pissing fuel. Had a little issue when i put a keyed hot to it and melted a wire so i have to find that short. I did what martins book said so it leads me to believe that its in the 5.0 harness, i bench tested the main harness and it doesn't short so I'm thinking it could be the fuel injection harness. I'll have to pull it tomorrow night.

Haven't worked on the brake booster, clutch line, cooling or exhaust yet.

Haven't worked on the brake booster, clutch line, cooling or exhaust yet.

#23

Turns out an a/c plug fits in an evap plug and i was shorting it out. Then i realized i had the dizzy 180 out, then i found out the tfi is shot. But it starts now, only for a minute though because its currently air cooled. Tomorrow I'll drop some coin on a radiator and driveshaft. Havent decided on a fan setup yet, but i did pickup a temp switch 170-185f, and a universal pipe thread. I was going to use one like martin suggests but its to hot 92-97c and if i want a cooler switch I would have a hard time finding the temp range and thread. Im definetly running parralel relays and seperate fuses with a manual bypass for the misserable manhatan/brooklyn/queens traffic I find myself in a few times a month.

#24

Last edited by Richharr; 08-23-2015 at 11:41 PM.

#25

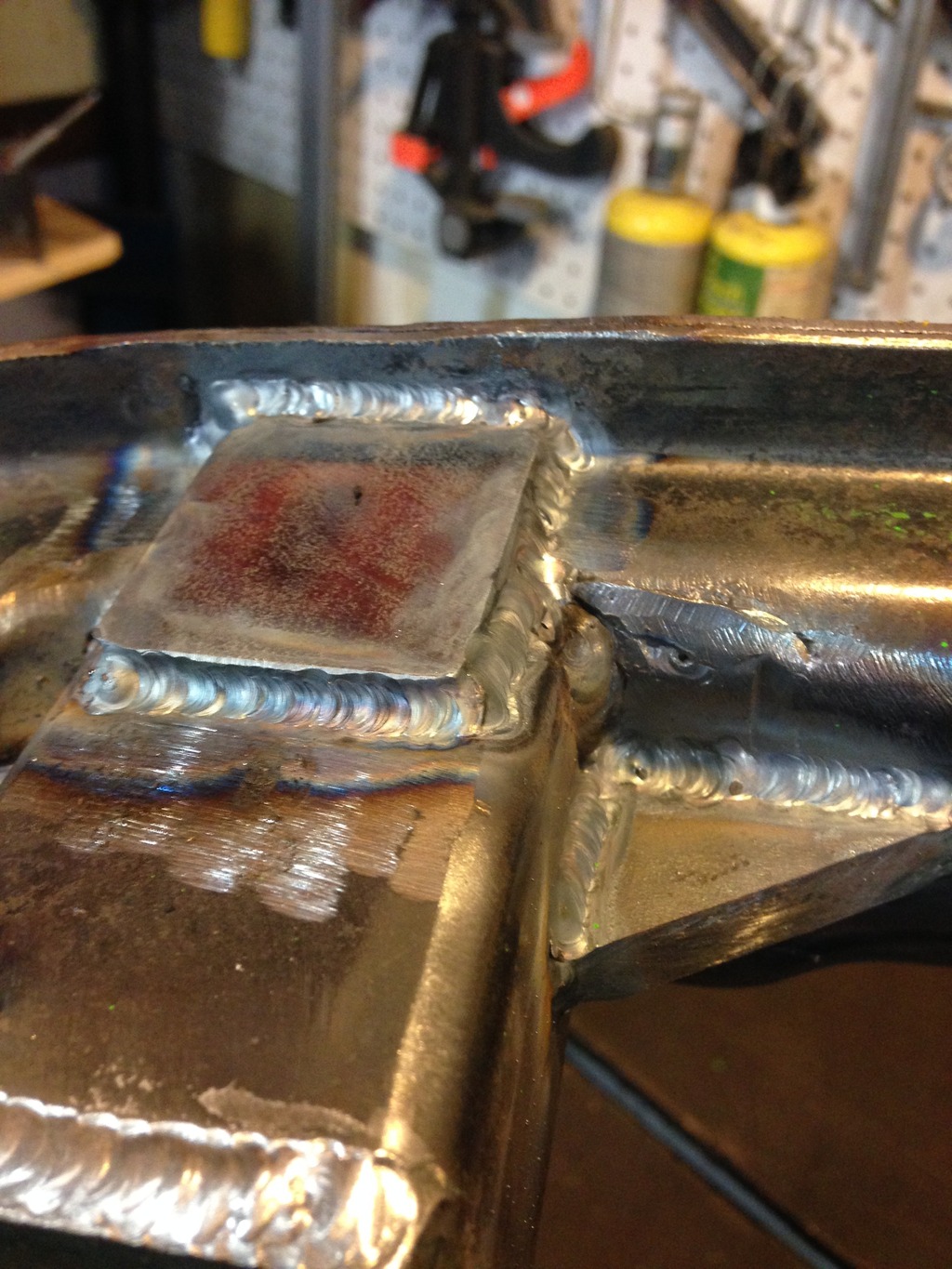

Waiting on an aluminum driveshaft from shaftmasters and a dual pass 3" aluminum radiator from saldanas. Figured if i bought a cheap radiator and steel driveshaft I would never upgrade, so it should be money well spent. Added a vdo oil pressure gauge and fuel pressure gauge, still waiting on the water temp. Finished the exhaust minus o2 bungs because I didnt have the tap. The exhaust is 2.5" steel, I used 2 j bends and about 14' of straight. All tig welded just because I had a full tank of argon and its soothing to do. The cans were free from a friend who only used them a week before changing his mind. I welded them together for a center exit, not for ascetics, just because its a super simple setup. I still need to add hangers to the center but im going to wait till I get the driveshaft.

This is a video, cant figure out how to make it work

http://s216.photobucket.com/user/richharr21/media/Mobile%20Uploads/2015-08/DC11FE42-C46A-4972-8791-E62AE9E15CB8.mp4.html

This is a video, cant figure out how to make it work

http://s216.photobucket.com/user/richharr21/media/Mobile%20Uploads/2015-08/DC11FE42-C46A-4972-8791-E62AE9E15CB8.mp4.html