Rear subframe brace into a '90

#1

My '90 has no rear subframe brace or provisions to fit one. What are you guys doing for bracing? I assume a stock brace fits OK with a 7.5" diff and Martin's mounting hardware? I'll be dropping my subframe to mount my diff this week and if I need to weld on any brackets or bolts etc now will be the time to do it.

Thanks,

Brad

Thanks,

Brad

#3

Researching this a bit, apparently Mazda made or makes a tab mounting kit for the earlier subframes to accept a later brace. I'm currently in the hunt for said kit.

Anyone here work at a Mazda dealership? I have a part number.

BTW Mike, I visited Pete with the P1800 a few weeks back. Very nice subframe you provided. That is one extensive undertaking he is doing.

Anyone here work at a Mazda dealership? I have a part number.

BTW Mike, I visited Pete with the P1800 a few weeks back. Very nice subframe you provided. That is one extensive undertaking he is doing.

#4

Any chance of finding a newer sub in a bone yard with the stuff already there? Actually all they are is a couple of tabs with nuts welded on them and they would be easy to make.

Mine is braced every which way but sunday but I just got carried away playing with the welder...

Mine is braced every which way but sunday but I just got carried away playing with the welder...

#5

#6

By the time i saw it last night, he already had a buyer. Plus not a great deal. The tab kits are only $100 from the dealer....cheaper if you look around, and used braces are practically free.

That's ok I may have one coming from a forum member here for a good deal.

That's ok I may have one coming from a forum member here for a good deal.

#8

I saw a post on grassroots where Keith (from FM) claims he can tell when a a tech has left the brace off the rear. I don't take every word I read on the internet as Gospel, but having met him, he doesn't come off a BS'r when it comes to these things. ...wants to sell their products, yes. But I see no $$ to be earned in the comment.

#10

I'm bringing this back, as i have freaking HORRIBLE wheel hop and my subframe has no OE mounting tabs for my oem diff brace.. Thinking about ordering the FM diff brace and welding in some 1" tubing...

I'm on Koni race struts and 325lb rear springs. Stock rear bar... My rear hops with even the SLIGHTEST big of throttle. HELLLLLP

I'm on Koni race struts and 325lb rear springs. Stock rear bar... My rear hops with even the SLIGHTEST big of throttle. HELLLLLP

#11

I'm bringing this back, as i have freaking HORRIBLE wheel hop and my subframe has no OE mounting tabs for my oem diff brace.. Thinking about ordering the FM diff brace and welding in some 1" tubing...

I'm on Koni race struts and 325lb rear springs. Stock rear bar... My rear hops with even the SLIGHTEST big of throttle. HELLLLLP

I'm on Koni race struts and 325lb rear springs. Stock rear bar... My rear hops with even the SLIGHTEST big of throttle. HELLLLLP

#13

I'm bringing this back, as i have freaking HORRIBLE wheel hop and my subframe has no OE mounting tabs for my oem diff brace.. Thinking about ordering the FM diff brace and welding in some 1" tubing...

I'm on Koni race struts and 325lb rear springs. Stock rear bar... My rear hops with even the SLIGHTEST big of throttle. HELLLLLP

I'm on Koni race struts and 325lb rear springs. Stock rear bar... My rear hops with even the SLIGHTEST big of throttle. HELLLLLP

Pics would be helpful. You need to create a box around the diff from control arm to control arm across the width. A cobra style diff housing cover that bolts to a bracket connected to a solid mount is also an excellent add on.

Upgrade control arm bushings noted above are also a good upgrade, along w/poly diff bushings.

Another thing that I've shared over the years are welding 1/8" thick plates to fill the space between the lower control arm arms. This helps to keep the stock arms from twisting.

An extreme mod would be to tie the lower control arms to the frame rails w/ a pipe (heim joints @ each end) to keep the LCA from twisting while allowing normal suspension travel.

#14

I'm bringing this back, as i have freaking HORRIBLE wheel hop and my subframe has no OE mounting tabs for my oem diff brace.. Thinking about ordering the FM diff brace and welding in some 1" tubing...

I'm on Koni race struts and 325lb rear springs. Stock rear bar... My rear hops with even the SLIGHTEST big of throttle. HELLLLLP

I'm on Koni race struts and 325lb rear springs. Stock rear bar... My rear hops with even the SLIGHTEST big of throttle. HELLLLLP

Do you have your trans brace supported through the floor at the edge of the foot wells? I have no idea why but Jason says that makes a big difference. Maybe not so much on LS cars as Fords but it is an easy measure to add. Basically you just run a bolt though the floor and your trans brace at the edge of the tunnel where it is about 3 layers thick. More footage of that here if you want to see the concept. Jim and Jenna build diary, Miata LS1 Conversion: The mother of all transmission mounts!

Other than that +1 on the bushings. Poly makes a big difference. That being said mine are OEMs with 200,000 miles on them but I used poly in other cars and it will help. I would at least make sure they are good.

What tires and diff mount are you using and what are you diff bushings like? Does it wheel hop breaking at all?

#16

I think it's a band-aide. You have a problem somewhere. I have the same diff and 430whp on 225/45/15 RA1's and zero wheel hop. IMO you either have a bushing that's allowing movement or its possible not having the rear brace is an issue -that's the only structural difference we have. ...that said...that brace isn't expensive and less labor than tearing down the rear so why not. If it helps I'd be curious to know as I'd be willing to add some bracing to mine too just to have it.

#18

....there's a parallel conversation going on on FB....

#19

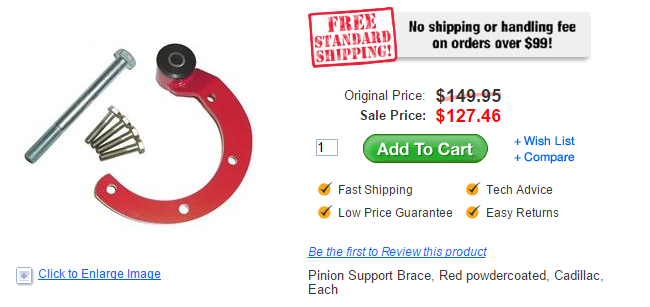

The pinion support brace that you posted will do the same thing as a Cobra style cover & should be used. However, you need to post a couple of pics (as has been requested). If your diff frame is poorly laid out (needs to be boxed & tied to the unibody),it will need more structure, as noted earlier. With pics, this can be resolved much sooner than later.

Last edited by 523-LSX-NB; 01-01-2015 at 05:19 PM.

#21

What I see from the video is a diff bolted to very thin brackets. Under load the diff is probably flexing those mounting points. Can't see much of the brackets that hold the ears of the diff, but caught a glimpse as you passed one near the end of the video. All look very thin. Those brackets should be @ least 1/4" thick or shore up the existing brackets w/ a perpendicular rib. I'd also use that diff brace you posted earlier. A higher durometer bushing wouldn't hurt either...the red bushings are usually in the 90-100 durometer range.

That is the minimum & should take care of the immediate problem. Next would be the box & then plate between the control arm legs. If you weld the 1/8" plate between the lower control arm legs from the arc to the bushings, this will keep you from needing the missing cross piece that would have run tab to tab & will help resist twist.

That is the minimum & should take care of the immediate problem. Next would be the box & then plate between the control arm legs. If you weld the 1/8" plate between the lower control arm legs from the arc to the bushings, this will keep you from needing the missing cross piece that would have run tab to tab & will help resist twist.

#24

Great video and your exhaust is not half as bad as mine!

The tabs you zero in on at 1:10 and talk about look like you could get a washer or 2 in them to tighten things up. Anything you can do to tighten up slop in the diff mounts will help more than bracing the subframes together IMO.

I don't know that the tabs are in your photo of post 22 ^^ because I am not very familiar with this set up but I know wheel hop well enough to know that is a bad deal. I can **** more support than that! I also really don't like that there is no support at all on the back of the diff and twisting front to back is what you are trying to stop.

I know when T bird guys have wheel hop problems bolting the rear diff mount solid and makes a big difference for them. Those 2 horizontal bolts in the side of it stop all movement of the caged rubber in the mount.

I know it's not directly applicable but works to the theory that you don't want any rotation between diff and chassis at all. Rubber in mounts is not your friend and if you can eliminate diff movement you will eliminate your hop.

The tabs you zero in on at 1:10 and talk about look like you could get a washer or 2 in them to tighten things up. Anything you can do to tighten up slop in the diff mounts will help more than bracing the subframes together IMO.

I don't know that the tabs are in your photo of post 22 ^^ because I am not very familiar with this set up but I know wheel hop well enough to know that is a bad deal. I can **** more support than that! I also really don't like that there is no support at all on the back of the diff and twisting front to back is what you are trying to stop.

I know when T bird guys have wheel hop problems bolting the rear diff mount solid and makes a big difference for them. Those 2 horizontal bolts in the side of it stop all movement of the caged rubber in the mount.

I know it's not directly applicable but works to the theory that you don't want any rotation between diff and chassis at all. Rubber in mounts is not your friend and if you can eliminate diff movement you will eliminate your hop.

Last edited by charchri4; 01-02-2015 at 02:57 PM.