Rear Subframe Assembly Problem

#1

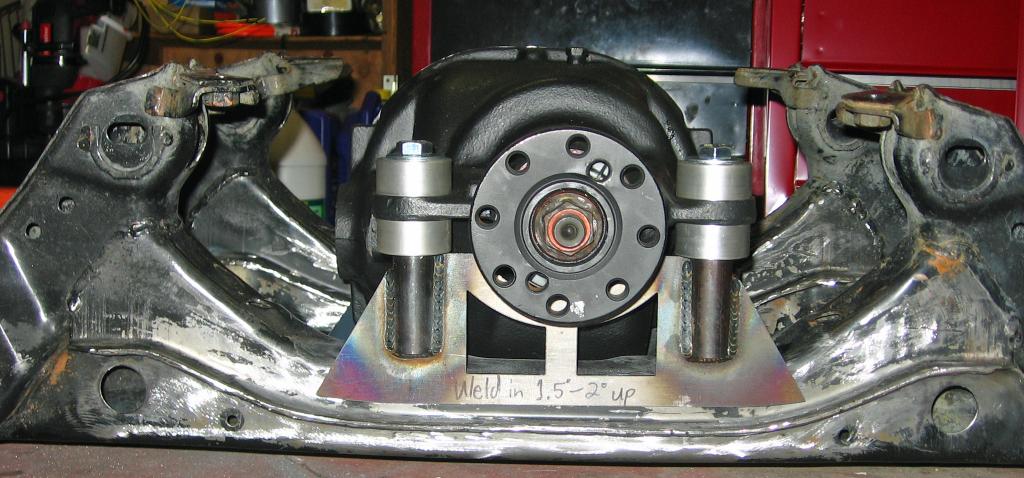

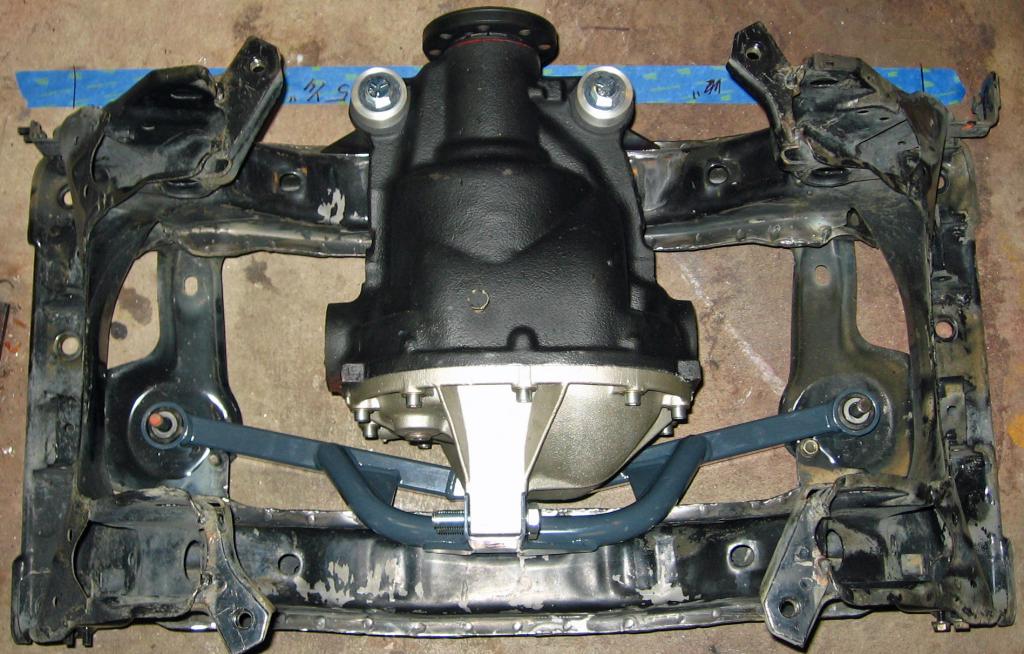

Today was the day to weld in the components for the rear sub frame. Warm weather is coming, and I'd be able to clean and paint this week end. Of course, there are problems.

First, the front mount is tapped for a 1/2" fine thread bolt. I didn't have any of those, so I had to make another trip to Ace Hardware.

Then, I discovered that there must be some kind of bushing that goes here. Obviously, I don't have any of those, either. Not sure what I'll do about that. I'm considering welding in some steel plate for a solid mount. For mock up, I slipped in a couple of old rubber suspension bushings.

Once I get everything mocked up, I find that's it's off center by about 1/2" or so.

I can probably live with that. But the other issue is that the front legs don't sit on the frame properly.

This one sits on the frame properly

But this one does not. It can be shimmed before welding without too much difficulty.

Is this normal? Should I install as is? Or should I cut off factory studs and move everything over 1/2"?

First, the front mount is tapped for a 1/2" fine thread bolt. I didn't have any of those, so I had to make another trip to Ace Hardware.

Then, I discovered that there must be some kind of bushing that goes here. Obviously, I don't have any of those, either. Not sure what I'll do about that. I'm considering welding in some steel plate for a solid mount. For mock up, I slipped in a couple of old rubber suspension bushings.

Once I get everything mocked up, I find that's it's off center by about 1/2" or so.

I can probably live with that. But the other issue is that the front legs don't sit on the frame properly.

This one sits on the frame properly

But this one does not. It can be shimmed before welding without too much difficulty.

Is this normal? Should I install as is? Or should I cut off factory studs and move everything over 1/2"?

#2

As far as centering goes, the important reference points are the flats where the axles plug in. The axles are undoubtedly the same length, so that area should be "centered". Given that, the pinion will always be off center, that's part of the design and perfectly acceptable.

HTH, Mike

HTH, Mike

#3

OK, that makes sense. The main part of the case does seem to be centered. IIRC, when I looked at the XXXocet, the transmission appeared to be shifted a smidgen to the left as well.

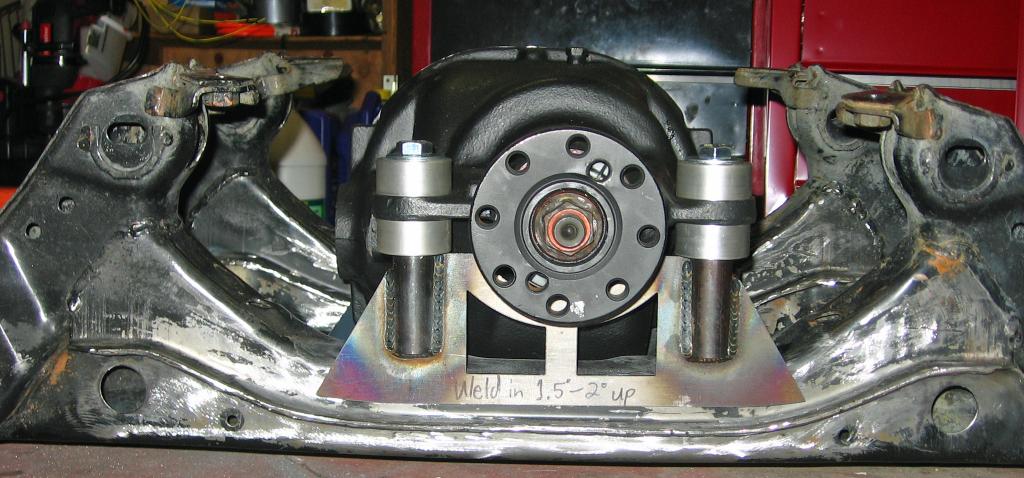

I don't particularly like the fit of the front brace. I'll do some trimming and shimming before I weld it all in place.

On the front of the brace, it says to weld it in 1.5-2* up. Meaning (I assume) that the pinion should be pointed upward by that much. I think I'll put a washer or two between the bushing and the brace. That way I can adjust the pinion angle more easily later on.

I don't particularly like the fit of the front brace. I'll do some trimming and shimming before I weld it all in place.

On the front of the brace, it says to weld it in 1.5-2* up. Meaning (I assume) that the pinion should be pointed upward by that much. I think I'll put a washer or two between the bushing and the brace. That way I can adjust the pinion angle more easily later on.

#4

I'd guess you would need to know where that measurement should be taken from. It's unlikely that the whole rear end would have to be pointed 1 1/2" up in the front. An imaginary line thru the pinion shaft should be parallel to a similar imaginary line thru the trans/crankshaft centerline. Not in line, just parallel.

Mike

Mike

#5

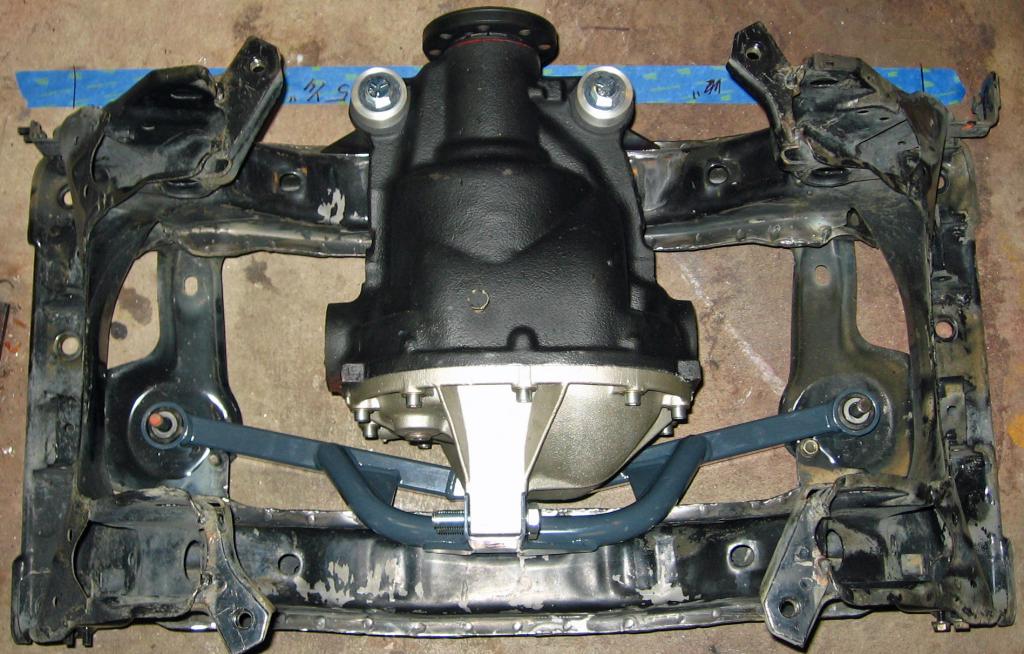

I finally got the job done. Took most of the afternoon. Mostly because I'm a bit OCD about proper fit before welding. Grind a little... trial fit. Grind a little... trial fit. a 16th here, a 32nd there, eventually it fits just right.

My welds are not particularly pretty, but they are effective. And I can grind really good.

I installed it with the pinion pointing up 1.5*. Depending on the power angle of the drive line, that should be pretty darned close to the proper pinion angle. I hope. If not, it's not a big deal to make adjustments.

I sent an e-mail to V* Roadsters this afternoon, asking what bushing goes in that big hole. I thought it would be a Miata bushing that I don't have because I'm not working with a donor. Their reply was a FedEx notice! They shipped out the proper bushings right away! I'm pretty impressed.

Speaking of V8R, they're impressive. Last week I sent them an e-mail asking about some shipping damage to a rear hub. I think it was cosmetic damage only (which I don't care about), but wasn't sure. Their reply was to have The Drive Shaft Shop drop ship me a new one! And I got the new one from UPS just a couple of days later. And it included a return shipping label. Very impressive.

My welds are not particularly pretty, but they are effective. And I can grind really good.

I installed it with the pinion pointing up 1.5*. Depending on the power angle of the drive line, that should be pretty darned close to the proper pinion angle. I hope. If not, it's not a big deal to make adjustments.

I sent an e-mail to V* Roadsters this afternoon, asking what bushing goes in that big hole. I thought it would be a Miata bushing that I don't have because I'm not working with a donor. Their reply was a FedEx notice! They shipped out the proper bushings right away! I'm pretty impressed.

Speaking of V8R, they're impressive. Last week I sent them an e-mail asking about some shipping damage to a rear hub. I think it was cosmetic damage only (which I don't care about), but wasn't sure. Their reply was to have The Drive Shaft Shop drop ship me a new one! And I got the new one from UPS just a couple of days later. And it included a return shipping label. Very impressive.

Thread

Thread Starter

Forum

Replies

Last Post

stng_96

Parts For Sale

2

07-16-2015 11:42 AM

SinisterRoadster91

V8 Miata Engines

15

12-23-2014 10:53 AM

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)