T56 + CTS diff leak, ideas?

#1

Hey everyone, I'm hoping someone has some insight on some of my teething issues with this car, as it's the little things that are driving me nuts!!! I've split them into separate tranny and diff issues/suggestions I've already tried so hopefully this isn't too confusing.

TRANNY (T56--used, 6 spd, unknown miles but upgraded pieces inside):

I've had a tranny leak since I put the car together and have tried to remedy it to no avail. It leaks tranny fluid out of the plug in the end of the yoke, right by the U-joint.

I've read that this plug (yes, the yoke is drilled all the way through) is essential to allowing air to escape as the driveshaft moves in and out of the tranny (which looks like is almost an INCH to me), and it shouldn't be sealed up (I was going to seal it).

Tranny does not leak around the seal at the back or up top by the shifter, it is coming out of the plug.

Suggestion 1:

-Pull the driveshaft and put marine grease on the splines and reinstall--allowing about an inch at the rear of the splines in the yoke to be clear of grease for air movement.

Verdict after doing this: It still leaks. Maybe not AS much, but enough to sling it 360* all over my tranny tunnel and have it drip down at the bottom of the tub. I also have a slightly less clunky tranny, now. The clunk was half the reason for pulling the shaft.

Suggestion 2:

-Perhaps it is overfull.

Verdict: If I take the fill plug out, a small amount of fluid dribbles out, as I filled it until fluid came out of the hole originally. The car has about 1000 miles on it so far and it's still slinging fluid, I would think by now it would have remedied itself if that was the case.

Suggestion 3:

-Maybe the tranny is somehow pressurizing/tranny vent clogged.

Verdict: I can't get to the vent on the T56 (up by bellhousing) but I can tell you when I remove the fill plug, it doesn't hiss or let any pressure out.

Pictures of offending plug (you can see the fluid on the edge inside) and my tunnels tranny fluid bath:

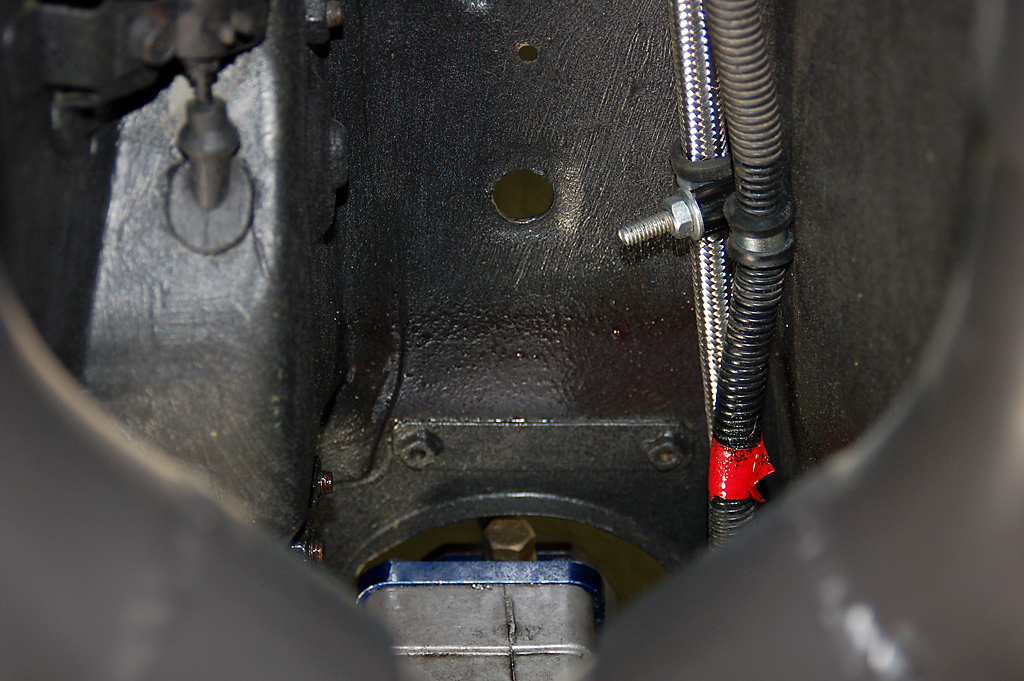

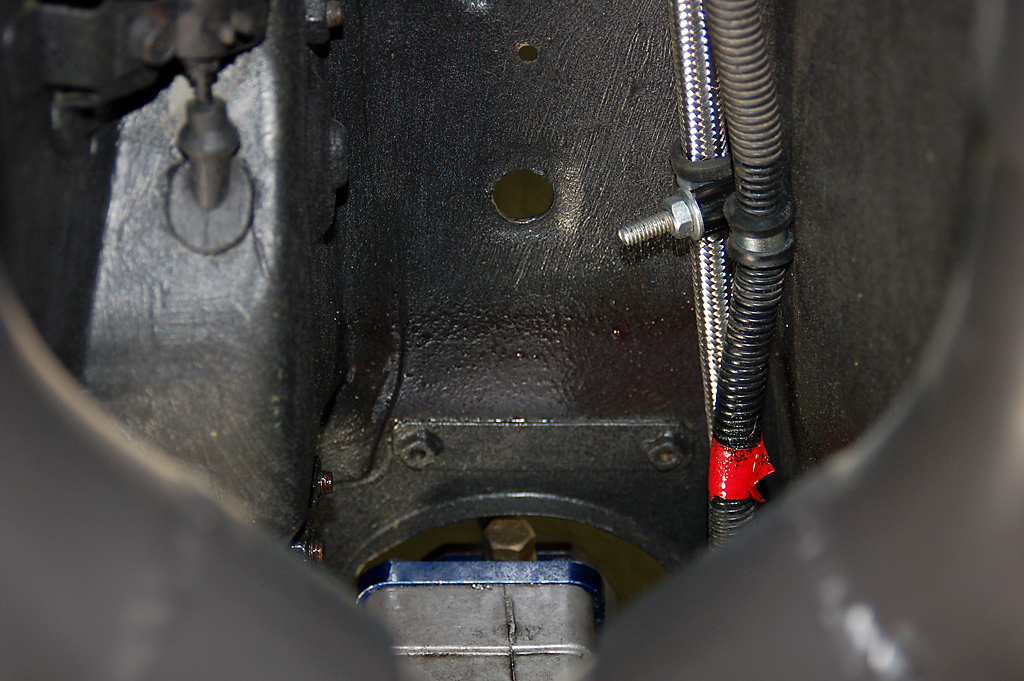

DIFF (CTS--used 3.42, 5x,xxx miles):

I noticed I had a fair amount of diff fluid on my skidplate I installed under the car and decided to take it down and have a look.

It is leaking out of the front seal and dripping down a good amount. I unscrewed the fill plug and it hissed like there was pressure inside.

I originally made sure to get a section of fuel line AND a brand new vent from the dealer ($30 for that little piece!) and put it on the nipple on the diff where the original vent was and ran it on top of the subframe and ziptied it in place. I took it down today to make sure it worked, and it does. Blow hard enough through it and it opens to let the air through.

Thought 1:

The exhaust is causing the diff to get too hot and pressurizing it/thinning the fluid enough to cause it to leak past the front seal.

Verdict: Bought heat-shielding and installed it and also made some custom shielding (fiberglass 1/2 pipe wraps that attach with clamps right next to the diff/aluminum shielding around the pipes directly in front of the diff), in addition to adding holes in the skidplate directly under the diff. Not really sure if it helped my issue at all but it should have cooled things down a bit. The custom aluminum covers were only 58*F after I came home from a drive.

Thought 2:

That nipple is so short, perhaps my hose came dislodged off of it? I would ASSUME that the nipple would then leak fluid *****-nilly (instead of not vent at all), which it has not done.

Verdict: There is no fluid on the back of the diff where the nipple is.

Thought 3:

Vent could have been clogged.

Verdict: I stuck a very small straw into the vent, and it went in far enough (a few inches) that it shouldn't be clogged.

Leak:

Skidplate:

I am really at a loss. I ordered a NACA duct and was planning on putting it in the skid plate in front of the fuel tank so I can direct some cool air at the tank and subsequently, the diff also. That project will happen tomorrow.

Stay tuned for another thread about fuel boiling in a separate section. In the meanwhile, ANY insight would be extremely helpful, as the car is really starting to **** me off with issues it seems no one else has.

In the meanwhile, ANY insight would be extremely helpful, as the car is really starting to **** me off with issues it seems no one else has.

TRANNY (T56--used, 6 spd, unknown miles but upgraded pieces inside):

I've had a tranny leak since I put the car together and have tried to remedy it to no avail. It leaks tranny fluid out of the plug in the end of the yoke, right by the U-joint.

I've read that this plug (yes, the yoke is drilled all the way through) is essential to allowing air to escape as the driveshaft moves in and out of the tranny (which looks like is almost an INCH to me), and it shouldn't be sealed up (I was going to seal it).

Tranny does not leak around the seal at the back or up top by the shifter, it is coming out of the plug.

Suggestion 1:

-Pull the driveshaft and put marine grease on the splines and reinstall--allowing about an inch at the rear of the splines in the yoke to be clear of grease for air movement.

Verdict after doing this: It still leaks. Maybe not AS much, but enough to sling it 360* all over my tranny tunnel and have it drip down at the bottom of the tub. I also have a slightly less clunky tranny, now. The clunk was half the reason for pulling the shaft.

Suggestion 2:

-Perhaps it is overfull.

Verdict: If I take the fill plug out, a small amount of fluid dribbles out, as I filled it until fluid came out of the hole originally. The car has about 1000 miles on it so far and it's still slinging fluid, I would think by now it would have remedied itself if that was the case.

Suggestion 3:

-Maybe the tranny is somehow pressurizing/tranny vent clogged.

Verdict: I can't get to the vent on the T56 (up by bellhousing) but I can tell you when I remove the fill plug, it doesn't hiss or let any pressure out.

Pictures of offending plug (you can see the fluid on the edge inside) and my tunnels tranny fluid bath:

DIFF (CTS--used 3.42, 5x,xxx miles):

I noticed I had a fair amount of diff fluid on my skidplate I installed under the car and decided to take it down and have a look.

It is leaking out of the front seal and dripping down a good amount. I unscrewed the fill plug and it hissed like there was pressure inside.

I originally made sure to get a section of fuel line AND a brand new vent from the dealer ($30 for that little piece!) and put it on the nipple on the diff where the original vent was and ran it on top of the subframe and ziptied it in place. I took it down today to make sure it worked, and it does. Blow hard enough through it and it opens to let the air through.

Thought 1:

The exhaust is causing the diff to get too hot and pressurizing it/thinning the fluid enough to cause it to leak past the front seal.

Verdict: Bought heat-shielding and installed it and also made some custom shielding (fiberglass 1/2 pipe wraps that attach with clamps right next to the diff/aluminum shielding around the pipes directly in front of the diff), in addition to adding holes in the skidplate directly under the diff. Not really sure if it helped my issue at all but it should have cooled things down a bit. The custom aluminum covers were only 58*F after I came home from a drive.

Thought 2:

That nipple is so short, perhaps my hose came dislodged off of it? I would ASSUME that the nipple would then leak fluid *****-nilly (instead of not vent at all), which it has not done.

Verdict: There is no fluid on the back of the diff where the nipple is.

Thought 3:

Vent could have been clogged.

Verdict: I stuck a very small straw into the vent, and it went in far enough (a few inches) that it shouldn't be clogged.

Leak:

Skidplate:

I am really at a loss. I ordered a NACA duct and was planning on putting it in the skid plate in front of the fuel tank so I can direct some cool air at the tank and subsequently, the diff also. That project will happen tomorrow.

Stay tuned for another thread about fuel boiling in a separate section.

In the meanwhile, ANY insight would be extremely helpful, as the car is really starting to **** me off with issues it seems no one else has.

In the meanwhile, ANY insight would be extremely helpful, as the car is really starting to **** me off with issues it seems no one else has.

Last edited by XCLR8TN; 09-28-2013 at 01:03 AM.

#3

OK but you should have a thread somewhere with exhaust that beautiful!

QUALIFY - I know just enough about t56s to be dangerous. My guess (emphasis on guess) is the bushing type seal inside the extension housing of the transmission. You usually you get a spit of oil out of the back of the trans on hard excel when it's bad. The part number is 24207915 for the T56 (and many more applications.) ACDelco 24207915 ~ Case Bushing It's cheap but a bit of work to put it in. Putting it in the freezer and your tail housing in the oven makes life better in the install.

Oh and put synchromesh oil back in it when you are done rather than ATF. http://www.summitracing.com/parts/na...FQ1gMgodtzQAYA A lot of parts stores carry the Pennzoil version and since they make it for GM it's fine to use too.

No clue on the diff but would love to see your skid plate! As in build thread...

QUALIFY - I know just enough about t56s to be dangerous. My guess (emphasis on guess) is the bushing type seal inside the extension housing of the transmission. You usually you get a spit of oil out of the back of the trans on hard excel when it's bad. The part number is 24207915 for the T56 (and many more applications.) ACDelco 24207915 ~ Case Bushing It's cheap but a bit of work to put it in. Putting it in the freezer and your tail housing in the oven makes life better in the install.

Oh and put synchromesh oil back in it when you are done rather than ATF. http://www.summitracing.com/parts/na...FQ1gMgodtzQAYA A lot of parts stores carry the Pennzoil version and since they make it for GM it's fine to use too.

No clue on the diff but would love to see your skid plate! As in build thread...

Last edited by charchri4; 09-28-2013 at 08:57 AM.

#4

QUALIFY - I know just enough about t56s to be dangerous. My guess (emphasis on guess) is the bushing type seal inside the extension housing of the transmission. You usually you get a spit of oil out of the back of the trans on hard excel when it's bad. The part number is 24207915 for the T56 (and many more applications.) ACDelco 24207915 ~ Case Bushing It's cheap but a bit of work to put it in. Putting it in the freezer and your tail housing in the oven makes life better in the install.

Oh and put synchromesh oil back in it when you are done rather than ATF. http://www.summitracing.com/parts/na...FQ1gMgodtzQAYA A lot of parts stores carry the Pennzoil version and since they make it for GM it's fine to use too.

No clue on the diff but would love to see your skid plate! As in build thread...

Oh and put synchromesh oil back in it when you are done rather than ATF. http://www.summitracing.com/parts/na...FQ1gMgodtzQAYA A lot of parts stores carry the Pennzoil version and since they make it for GM it's fine to use too.

No clue on the diff but would love to see your skid plate! As in build thread...

I've got dexron III in it, I bought a case the original GM part # to ensure I got the REAL dexron III, since the license expired.

Thank you for the response! I can sit down and make a build thread. I have one on a few other forums but it's 28 pages and cluttered with comments...

#5

Yeah my trans builder told me dex III has stuff in it for autos that your t56 doesn't appreciate. Checking out the description of syncromesh I think he has a point.

Anyway I have never had one apart in the car to know if you could pull the tail housing off in the car or not. I think you might be able to but I have done just enough trans work to know it's worth it to pay a pro that can do it in his sleep. Something like this I might try but I wouldn't go one inch farther in a T56 again. Maybe google around on changing that part number and see what you get. I know the bushing is there and it is recommended to be changed if changing the seal doesn't stop a leak but that's about it!

If you grab your drive shaft yoke and push it up and down is that any movement in it at all? Actually now that I think about that oil would probably run out if there was but worth a check. Also see if there is any binding of the yoke going in that might indicate the bushing being a bit off or out of round. Maybe when it was rebuilt they used an aftermarket one that is not quite right. You might call a builder like Tick, TDP or any number of good local shops and ask about it.

Anyway I have never had one apart in the car to know if you could pull the tail housing off in the car or not. I think you might be able to but I have done just enough trans work to know it's worth it to pay a pro that can do it in his sleep. Something like this I might try but I wouldn't go one inch farther in a T56 again. Maybe google around on changing that part number and see what you get. I know the bushing is there and it is recommended to be changed if changing the seal doesn't stop a leak but that's about it!

If you grab your drive shaft yoke and push it up and down is that any movement in it at all? Actually now that I think about that oil would probably run out if there was but worth a check. Also see if there is any binding of the yoke going in that might indicate the bushing being a bit off or out of round. Maybe when it was rebuilt they used an aftermarket one that is not quite right. You might call a builder like Tick, TDP or any number of good local shops and ask about it.

Last edited by charchri4; 09-28-2013 at 11:23 AM.

#6

Jim, Here is the asked-for build thread. It's one that I've followed for a year +. You can find details on Jess's LS6 here: 91 BRG LS6 Build - Page 28 - ClubRoadster.net

I hope you find some easy answers for these 2 concerns!

I hope you find some easy answers for these 2 concerns!

#7

Since the transmission is vented at the bellhousing area, I would clean & cover the hole at the u-joint with silicone sealer.

For the differential, I would install an open nipple with a long hose in place of the GM vent set-up & see what happens.

For the differential, I would install an open nipple with a long hose in place of the GM vent set-up & see what happens.

#8

Since the rear end and the trans are more or less solidly mounted, the driveshaft doesn't move back and forth like it does in a "conventional" solid axle, there is no problem sealing the yoke.

Mike

#9

Yeah my trans builder told me dex III has stuff in it for autos that your t56 doesn't appreciate. Checking out the description of syncromesh I think he has a point.

If you grab your drive shaft yoke and push it up and down is that any movement in it at all? Actually now that I think about that oil would probably run out if there was but worth a check. Also see if there is any binding of the yoke going in that might indicate the bushing being a bit off or out of round. Maybe when it was rebuilt they used an aftermarket one that is not quite right. You might call a builder like Tick, TDP or any number of good local shops and ask about it.

If you grab your drive shaft yoke and push it up and down is that any movement in it at all? Actually now that I think about that oil would probably run out if there was but worth a check. Also see if there is any binding of the yoke going in that might indicate the bushing being a bit off or out of round. Maybe when it was rebuilt they used an aftermarket one that is not quite right. You might call a builder like Tick, TDP or any number of good local shops and ask about it.

I took a video for what you asked about:

http://i971.photobucket.com/albums/a...ps8d495800.mp4

http://i971.photobucket.com/albums/a...f/IMG_8350.mp4

It's odd because it doesn't leak around the outside of the yoke, just at the plug in the end. No binding that I felt when I put it back in.

Is there a way to remove this?

thank you!

thank you!

#11

Jim, Here is the asked-for build thread. It's one that I've followed for a year +. You can find details on Jess's LS6 here: 91 BRG LS6 Build - Page 28 - ClubRoadster.net

I hope you find some easy answers for these 2 concerns!

I hope you find some easy answers for these 2 concerns!

In the video it looked like the driveshaft yoke has some movement up and down in it. Does it? There has to be a little slop or you would not be able to get the yoke in but I can see no visible movement in mine up and down when I push on it like that.

Are you sure you have a good seal on your shifter with some sort of gasket or RTV between it and the trans? I've had mine leak by in getting a good seal there before.

Yeah I've read a ton of debate on synthetic vs normal ATF etc on the trans oil and I have always used the same real Dex III you are using. There is nothing wrong with that at all and I was very surprised when my builder told me to use synchromesh. But it makes sense if you read the labels and think about it. ATF is designed for autos for clutch packs to work right. It will work in a t56 but the only reason they use it is to have one less oil on the assembly line. Never forget cars are designed first to be built as efficiently as possible. The same reason we have drive by wire and all the other stupid ideas that make cars easier to assemble but lousy to work on. Given the vast majority of cars are autos if they can get it down to the same oil in all of them it's a big gain in materials handling and assembly. Synchromesh was designed for manual transmissions for gears to mesh well and be oiled right. With its friction modifiers it is way too slippery and would be a disaster in an auto trans. Thus if the goal is one oil for all it has to be ATF even though it is not ideal for manuals. I’m not saying I’m right or any sort of expert but it kinda makes sense to me. Well that and the guy that did my trans only builds t56s and has a ton of them on the track… Actually you should be talking to him about the leak not me!

Last edited by charchri4; 09-30-2013 at 10:27 AM.

#12

LOL I have been following him nearly that long too! I didn't pick up on the name but would have recognized the sig pic green Miata anywhere. Too many forums but great build!!

In the video it looked like the driveshaft yoke has some movement up and down in it. Does it? There has to be a little slop or you would not be able to get the yoke in but I can see no visible movement in mine up and down when I push on it like that.

Are you sure you have a good seal on your shifter with some sort of gasket or RTV between it and the trans? I've had mine leak by in getting a good seal there before.

In the video it looked like the driveshaft yoke has some movement up and down in it. Does it? There has to be a little slop or you would not be able to get the yoke in but I can see no visible movement in mine up and down when I push on it like that.

Are you sure you have a good seal on your shifter with some sort of gasket or RTV between it and the trans? I've had mine leak by in getting a good seal there before.

I don't have my cartoon-me-with-cleavage pic on this forum like I do on CR.net hahaha!

I don't have my cartoon-me-with-cleavage pic on this forum like I do on CR.net hahaha!There is play up-down on the yoke... Last time I had it out I measured every dimension I could and determined the sides of the splines contact the sides on the tranny side, but the yoke spline ID I believe was .033" smaller than the input shaft spline OD. I assumed since the sides were touching, it should be fine. Now I'm going back to my original thought of buying another yoke and swapping it out. :/

As for the shifter, when I got the tranny it was loose and I tightened it up. There is very very very little fluid anywhere around it, honestly I think the mist on it that collects dirt is from the yoke slinging it and air moving it around. I'd like to replace the B&M but I don't feel like dropping the tranny!

#13

You should be able to swap the shifter from the top. Pop the boot off and there is plenty of room to get at it.

I was under mine tonight and grabbed the yoke and pushed up and down. Doesn't move even a little. I wonder if you can get a little larger yoke.

I was under mine tonight and grabbed the yoke and pushed up and down. Doesn't move even a little. I wonder if you can get a little larger yoke.

#14

And stuck it up onto the input shaft and wiggled it around. It's a little bit tighter. I guesstimated how far in it should go based on my other video and I think it is still tighter than the old one.

http://i971.photobucket.com/albums/a...psa7f943e5.mp4

OD is .002" larger. I know that doesn't help but it went in ever so slightly different. Who knows. I'll be happy once I get the U-joint out and yoke swapped.

#17

I would love to let you know but I'm not sure. Had cooling issues which allowed my temp tags to expire in the time it took to figure out and fix them so I haven't been able to drive it. From what I saw it seems to have fixed the tranny fluid leak but haven't really put enough miles on it to be 100% sure...

I also made a semi-big change to the diff mounting points and still need to see how those worked out. Basically I noticed the studs on the subframe had stripped at some point (really have no clue here, I remember torquing those nuts). Removed the stock M12 stud and replaced it with a stock LSx crank bolt (M16) and opened everything else up to accommodate the bigger stud.

I also made a semi-big change to the diff mounting points and still need to see how those worked out. Basically I noticed the studs on the subframe had stripped at some point (really have no clue here, I remember torquing those nuts). Removed the stock M12 stud and replaced it with a stock LSx crank bolt (M16) and opened everything else up to accommodate the bigger stud.

Thread

Thread Starter

Forum

Replies

Last Post

SC 97 M

V8 Miata Drivetrains

7

07-08-2015 06:15 PM

v8miatanet

V8 Miata Safety, Legal, & Emissions

9

02-06-2014 02:10 PM

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)